Software for the Ages

January 29, 2020Comments

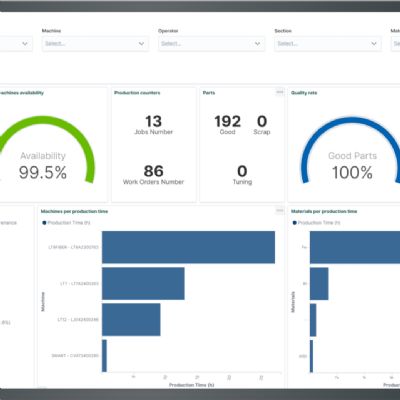

Fabricators and metal formers today use a broad range of equipment to meet production goals. Success in meeting these goals requires the right software.

|

| A CAD/CAM nesting software system, designed for automating the CNC programming of sheet metal fabricating machines, provides nesting algorithms and mechanization strategies for cutting and punching. |

MetalForming (MF): How are your customers trying to tie their various production equipment together to better schedule and track production?

Allen Vines (AV): Companies try to find software and vendors that they like and stick with to avoid switching to multiple software packages and having to relearn the wheel, so to speak. For example, our software vendor, Lantek, supports a range of manufacturers and equipment, so it is possible to have one software package running a CNC router, waterjet, press brake, shear and a laser.

MF: What is important to have in a nesting program for an imperfect manufacturing world, where part remakes are a reality?

AV: Good question. It is important to have a nesting program that provides the customer with the ability to pull certain parts out of the nest when necessary, whether it be tip-ups, a bad spot in the material, or whatever may cause an operator to need to remake a part. Perhaps an operator bends a part incorrectly. Placing a piece of scrap on the table, pulling the part out of an existing program, or even importing a new part via DXF, and running another one or two of those parts at the control without having to go to the programmer is a huge benefit of Lantek Expert Inside, for example. If used in conjunction with an active camera, a part can be pulled from the nest of good parts and then nest inside of other cutouts on the scrap material.

MF: How do modern nesting options help manufacturers?

AV: Back in the day, situations required a lot of manual input in the nesting software, and users had to know the machines a lot better. Now, software packages are written well enough so that just about anybody can bring in any drawing and create a usable program in just a few clicks. Just five or 10 years ago, fabricators would spend 20 to 30 minutes on one single part. Now, in 20 to 30 minutes fabricators have hundreds of parts nested and ready to go. In addition, integration of ERP software enables work orders in the office to feed into the nesting software on the manufacturing floor—with everything grouped together.

For a job shop with multiple customers running the same materials, different parts can be nested together to best utilize material. This reduces material cost and time spent by operators having to pull the materials, while still ending up with all of the needed parts at the end of the day. The ability to achieve a workflow that allows Customer A and Customer B orders to process together is a game-changer.