Combo Multiblanking Lines

December 1, 2019Comments

|

|

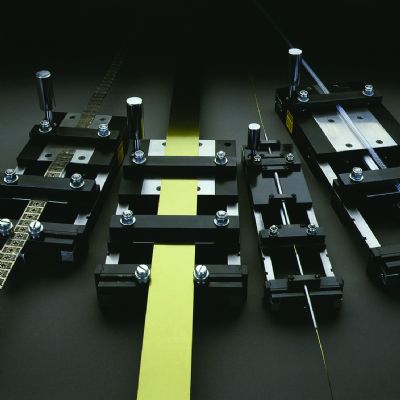

"To avoid delays caused by external suppliers, many of our customers demand the integration of slitting shears in their cut-to-length lines,” reports Thomas Baral, managing director of B+S GmbH. "Therefore, we have used the synergy effects of the individual companies of the B+S group to develop flexible systems for these high quality requirements.” With the new multiblanking systems, several precise and individual sheet metal blanks can be produced in one run.

Up to Five Strips at 100 m/min.

The multiblanking lines, designed for sheets with a material width of up to 2500 mm and 0.1 to 6.0 mm thick, combine a cut-to-length line with a slitting line. "Before the first cut, the coil is first leveled and then cut into longitudinal strips," explains Baral. "The strips then are cut crosswise, resulting in as many as five blanks per segment in the desired length. Due to the large number of sheet blanks with small dimensions, the stacking and packaging area plays an important role. We’ve paid attention to different stacking techniques such as a vacuum, magnetic tape or swing arm."

View Glossary of Metalforming Terms

See also: Burghardt + Schmidt GmbH

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingAndritz to Supply Cut-to-Length Line to Olympic Steel in Min...

February 11, 2025

Coil and Sheet Handling

Coil and Sheet HandlingPress Feed Strong

Kate Bachman Wednesday, April 23, 2025

Coil and Sheet Handling

Coil and Sheet Handling5 Questions About Air Feeds; 5 About Servo Feeds

Bradley Nordlof Thursday, April 17, 2025