Specific Cells for Specific Needs

“We ask fabricators what they are looking for when they consider automation,” says Reuther. “Do they want a small-cell approach, or a flexible logistics center that can be fed with orders where they manage just one inventory compared to three?”

Some fabricators may manufacture three main product lines, with each of them providing enough work for one or two dedicated laser-cutting machines. In this case, according to Reuther, it makes sense to operate them as independent cells.

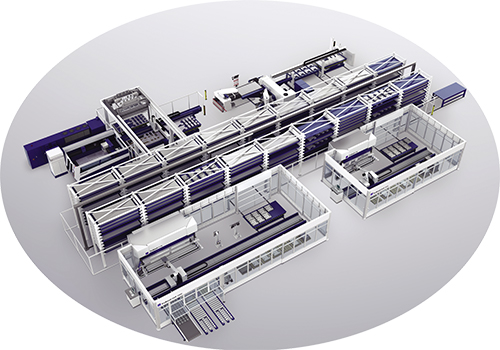

“Clearly distinctive production lines can benefit from this approach,” he says, “but it is not very flexible. With an A-B-C production line, what if production drops suddenly on A but increases on C? A fabricator can’t shift to the other cell without giving up efficiency and flow, and must change the inventory and ensure location of the right material in the right cell. A large storage system with six connected machines enables a fabricator to shift and prioritize work easily. Dedicated product lines benefit from smaller cells, but if jobs change frequently over time, multiple machines connected to a central storage center enable the needed flexibility.”

Such smaller cells, as cellular manufacturing may have been described a decade or more ago, were, back then and in many cases today, essentially production islands. Bridging those islands these days are advanced communication software and manufacturing execution systems (MESs) that allow cells to work in concert, bringing flexibility where previously it did not exist.

“Even multiple individual cells served by a couple of storage towers can connect to an MES,” Reuther says, “bringing a greater level of freedom and flexibility, thus making cellular manufacturing more powerful than ever.”

Optimized Layouts Serve Individual Sectors Well

Today, cellular-manufacturing layouts often reflect the industries served by fabricators.

“For example, agricultural manufacturers tend to produce distinct products that change little from year to year, using similar parts from similar materials in similar thicknesses,” Reuther explains. “These manufacturers know that these products will be manufactured for the next 10 to 15 years, so they focus on larger systems due to volume and the expectation of constant work.

“Appliance fabricators, on the other hand, deal with a much higher variety of parts,” he continues. “They place importance on quickly producing many part types. They tend to opt for several small cells that allow flexibility based on demand. Software connects these cells to help optimize productivity. And, with most material being thin-gauge stainless steel, it doesn’t matter if it is stored in three or four towers, or just one. Due to lack of material variety, inventory poses only a minor challenge.”

These examples illustrate how cellular layouts arise from various fabricator needs. Where agricultural suppliers may deal with known part types and volumes over an extended period but require a variety of materials in various thicknesses, appliance suppliers could face part variety but little material differentiation. Cell solutions exist for both. Some combination of these application attributes reveal other cellular possibilities, where the large system tackles high-volume, varied-material jobs while small cells run smaller-lot jobs.

Transparency Keys Cell Advancements

“Transparency is the key to production efficiency, especially in cellular environments,” explains Reuther. “Knowing how a machine performed on the last shift, knowing the idle times and errors…how do you find out?”

Smart factories, using the advanced communication capabilities in newer equipment, combined with software that tracks, analyzes and helps manage all aspects of operations, bring cellular manufacturing to a whole new level via transparency of processes, machine utilization and workflow. Machines or software can notify operators or management of issues, leading to almost instant response and resolution.

“That transparency dramatically reduces downtime and increases efficiency,” Reuther says. “Connectivity of machines that enable communication with a general software system is an absolute necessity for ideal shop-floor productivity. Otherwise, machines and processes would require constant monitoring by humans. Machines can ask for help or keep the system updated on job progress, ensuring that the next job will be ready to go.”

And, should troubles arise that can’t be solved inhouse, new technology such as remote monitoring by machine manufacturers, or augmental-reality glasses that let machine-builder technicians see what the fabricator sees, quicken troubleshooting and repair by leaps and bounds. The options cost less than flying a technician out to take a look. MF

View Glossary of Metalforming Terms

See also: TRUMPF Inc.

Technologies: Bending, Cutting, Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingCreative Approaches to Common Press Brake Challenges, Part 4...

Justin Talianek April 25, 2025