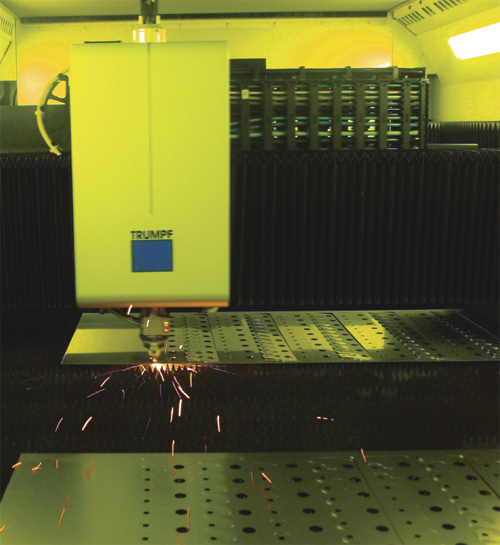

Trumpf

Trumpf

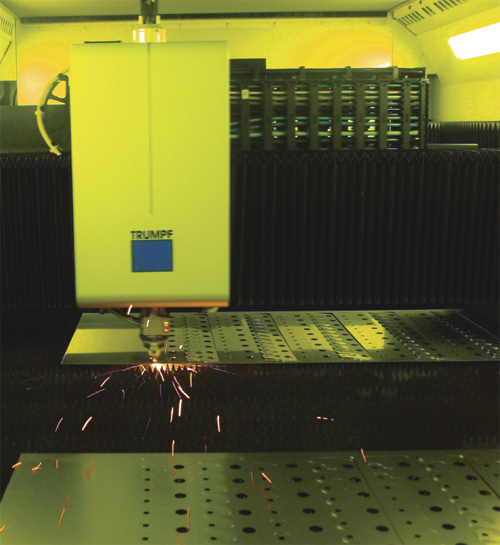

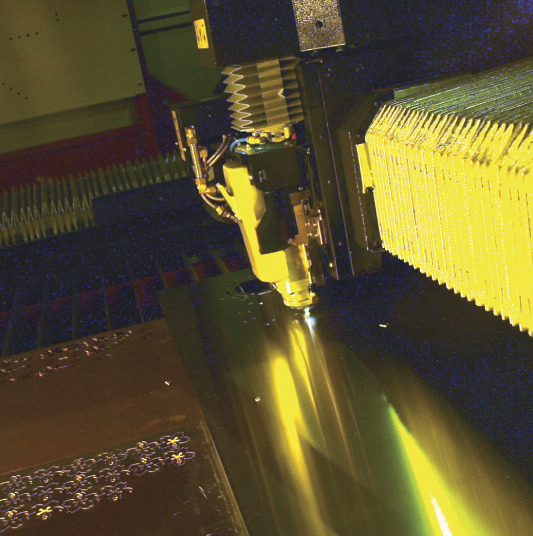

Trumpf, which announced that it had sold 12 machines off of the show floor on the first day alone, displayed its TruLaser 1030 solid-state disk-laser cutting machine, designed and built at its U.S. headquarters in Farmington, CT. The firm now offers the 2009-vintage TruLaser 1030 with either its 2-kW disk laser or a 2.5-kW CO2 laser. Also new for Fabtech is the TruLaser 3030 equipped with a 6-kW CO2 laser, and the TruLaser 5030 fiber, which boasts a fiber-guided TruDisk solid-state laser (not a fiber laser, but with the same solid-state beam characteristics as a fiber laser) rated to 3 kW, along with an automatic nozzle changer.

Mazak Optonics

Among the advancements dotting the Mazak Optonics booth was, first and foremost, its Optiflex 3015 4-kW fiber-laser cutting machine. Mazak personnel explained to showgoers how it manufactures the Optiflex 3015 Fiber in an underground, eco-friendly factory with ISO-4001 certification. Further adding to its eco-friendliness, the machine offers an 80-percent reduction in generator and chiller electrical power consumption when compared to conventional laser processing, we’re told. It includes a flexible, high-speed two-pallet changer that Mazak says is 58 percent faster than previous models. And, the torch, nozzle and pallet changing can occur simultaneously to minimize noncutting time.

Among the advancements dotting the Mazak Optonics booth was, first and foremost, its Optiflex 3015 4-kW fiber-laser cutting machine. Mazak personnel explained to showgoers how it manufactures the Optiflex 3015 Fiber in an underground, eco-friendly factory with ISO-4001 certification. Further adding to its eco-friendliness, the machine offers an 80-percent reduction in generator and chiller electrical power consumption when compared to conventional laser processing, we’re told. It includes a flexible, high-speed two-pallet changer that Mazak says is 58 percent faster than previous models. And, the torch, nozzle and pallet changing can occur simultaneously to minimize noncutting time.

The Optiplex 3015 is constructed using a building-block approach for capacity growth, so it easily integrates with Mazak’s automation equipment, also on display at Fabtech. The company’s new modular approach to automation equipment includes load-unload cells, flexible automation systems and automated parts sorting. The equipment is expandable and can accommodate as many as four cutting machines.

Hypertherm

Hypertherm announced to Fabtech visitors its expanded HyIntensity lineup of fiber-laser cutting machines, having unveiled a 1.5-kW machine at Fabtech in 2010. Now the firm offers a 2-kW model for thicker work and 1-kW model for thinner applications. HyIntensity systems are designed with the fiber laser supply, cutting head, automatic gas console, operator interface consoles, motion controls and software combined into one integrated package.

Ermaksan

Ermaksan used the Fabtech stage to showcase its new Fibermak fiber-laser cutting machine, boasting of energy consumption 70 percent less than cutting with CO2 lasers, and three times the cutting speed on thin sheet. Axes are equipped with linear motors and drives that allow travel speeds to 141 m/min. and accelerations to 2 G.

Ermaksan used the Fabtech stage to showcase its new Fibermak fiber-laser cutting machine, boasting of energy consumption 70 percent less than cutting with CO2 lasers, and three times the cutting speed on thin sheet. Axes are equipped with linear motors and drives that allow travel speeds to 141 m/min. and accelerations to 2 G.

Bystronic

The Bystronic BySprint Fiber 3015 fiber-laser cutting machine displayed at Fabtech is based on the firm’s BySprint Pro platform and its ByVention Fiber laser machine. Equipped with a 2-kW fiber laser, the BySprint Fiber 3015 shines when cutting material to 0.16-in. thick, say company representatives, while powerful enough to process sheet as thick as 0.50 in. As with other solid-state lasers, the laser beam is transported to the cutting head through a passive fiber, as opposed to the deflection-mirror systems employed by CO2 lasers. The result is lower operating and maintenance costs, in addition to significant energy savings. The specially designed cutting head has a focal length of 150 mm, enabling it to cut thin and thick material.

Also new from Bystronic are advanced mirror detection systems for its Bylaser 6000 6-kW CO2 laser: an end-mirror sensor and output-coupler sensor. These sensors monitor the conditions of the two most important mirrors in the resonator and shut down the resonator in the case of a fault, particularly useful when running an automated lights-out operation.

Waterjet Cutting Opens New Doors

Mitsubishi

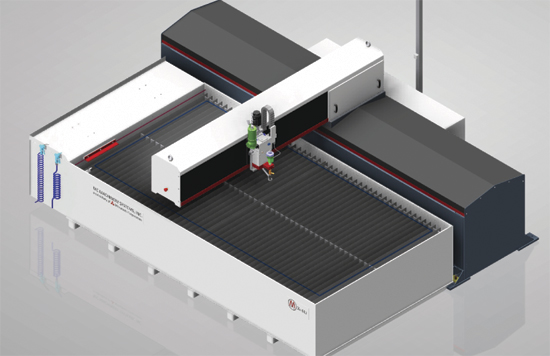

Those looking to expand beyond cutting and machining only metallic products, such as ceramics, composites, plastic, glass and stone, find waterjet cutting to be the process of choice. While discussing waterjet technology with the folks at the Mitsubishi booth at Fabtech, we learned about its new entry-level machine due to be introduced early in 2012. While not quite ready to be displayed at Fabtech, Mitsubishi personnel offer MetalForming readers this sneak preview.

Those looking to expand beyond cutting and machining only metallic products, such as ceramics, composites, plastic, glass and stone, find waterjet cutting to be the process of choice. While discussing waterjet technology with the folks at the Mitsubishi booth at Fabtech, we learned about its new entry-level machine due to be introduced early in 2012. While not quite ready to be displayed at Fabtech, Mitsubishi personnel offer MetalForming readers this sneak preview.

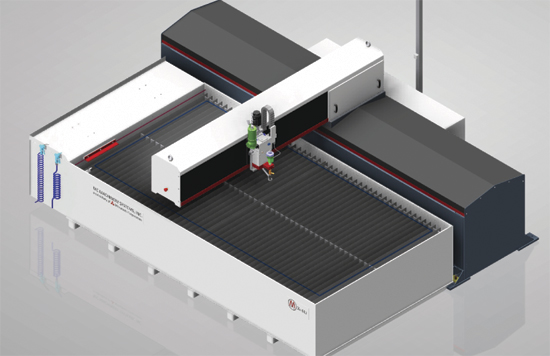

Dubbed the MW3, Mitsubishi’s new entry-level waterjet-cutting machine should prove ideal for production environments and customers new to waterjet, we’re told. “Its solid base construction and cantilever head design make it reliable and affordable,” say company officials. The machine is provided with a Model 720 CNC control boasting easy-to-use menu and help functions to guide operators through programming and workpiece setup.

The MW3 will come standard with a high-pressure S-50 KMT pump, which provides 60,000 PSI of water traveling up to Mach 2 with 1.09 gal./min. of water consumption through a maximum orifice size of 0.013 in. The reciprocating hydraulic piston to ceramic water piston ratio is 20:1, pushing the water into an accumulator that maintains a smooth, even flow to the cutting nozzle.

(KMT launched two new intensifier pumps at Fabtech: its Streamline Pro2 in 60- and 125-hp models, and the NeoLineTM40i 55,000-PSI pump that features a new, low-profile cabinet to ease operator access to controls and components.)

Techni Waterjet

Techni Waterjet featured its TJ3000-X2 waterjet-cutting machine at Fabtech, along with its Quantum ESP55 electric servo pump. New for the firm is its abrasive-delivery pump and hopper system, designed to eliminate all mechanical moving parts from contacting the garnet. This, say company officials, ensures consistent abrasive flow to the cutting head to optimize time between maintenance cycles. A clear pump chamber allows for quick visual inspection to confirm abrasive is present and flowing correctly.

Omax Corp.

Omax Corp.

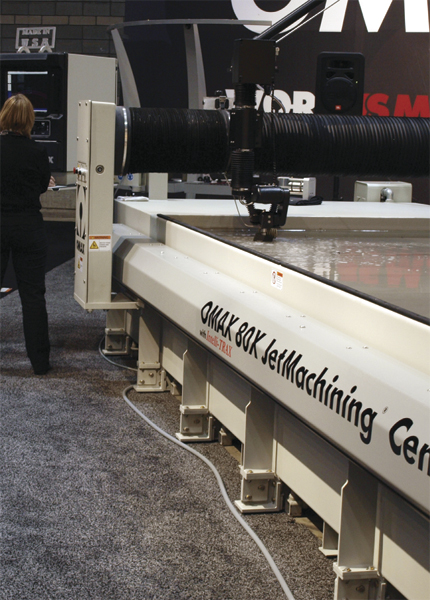

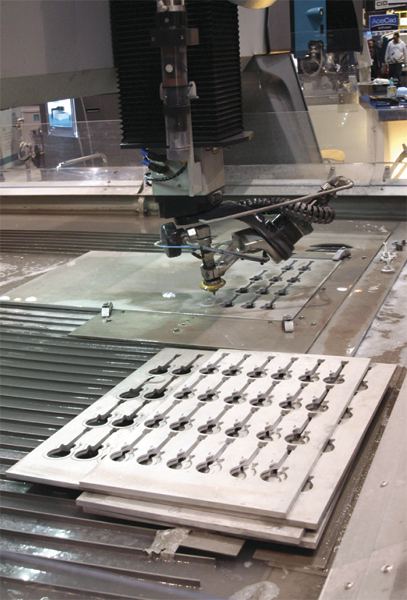

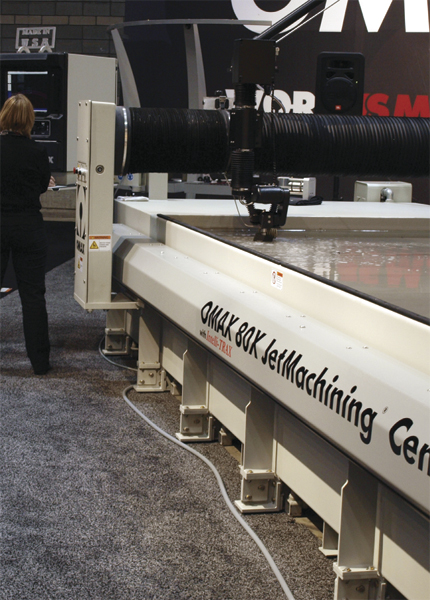

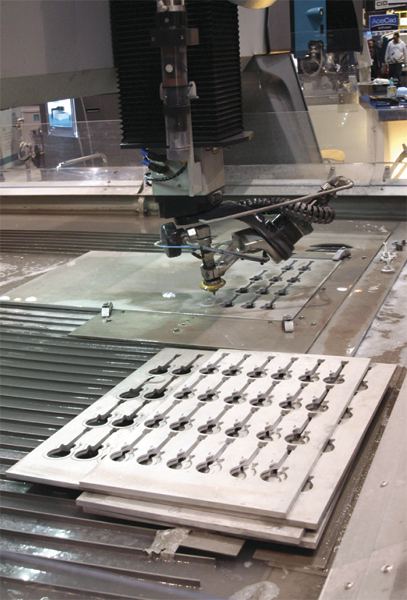

Omax Corp. demonstrated its 80X JetMachining Center to Fabtech attendees, equipped with a 50-hp EnduroMax pump and Tilt-A-Jet cutting head. Ideal for precision machining of large parts, the machine features a linear-drive package fully enclosed inside coated steel covers, making it a robust and reliable system well suited for harsh environments. It comes standard with the Omax Intelli-Max software running on Windows 7 Ultimate; motion accuracy is ±0.003 in.

Omax officials explained that the EnduroMax pump provides double the operating life of previous pumps, while enabling faster part processing at reduced operating costs. It’s rated for 1000 hr. of operation between pump rebuilds when run at 55,000 PSI.

The Tilt-A-Jet cutting head, say Omax officials, enables cutting with virtually zero taper by automatically calculating and adjusting the angle of the nozzle to transfer taper from the part being cut to the scrap material.

Also on display: the Omax Maxiem 1530 JetCuttingCenter equipped with an A-Jet multiaxis accessory that enables cutting of beveled edges and angles to a maximum of 60 deg. off vertical. Fabricators can use the software-controlled accessory to cut countersunk holes or for weld-edge preparation. Omax used the Fabtech stage to alert showgoers that it recently expanded its lineup of JetCuttingCenters with the addition of 16 new machines, the largest of which offers cutting areas from 160 by 320 in. to 160 by 640 in.

MultiCam Inc.

Another new entry-level waterjet-cutting system, also equipped with a KMT NeoLine direct-drive intensifier (this one a 10-hp 40,000-PSI model promoted as an economical low-cost option for light-duty cutting) was debuted by MultiCam Inc. Its new Value-series (or V-series) machine uses a pure water or abrasive cutting system for workpieces to 60 by 120 in. Says director of sales and marketing John Harris: “It’s easy on the budget and a smart CNC investment.”

Fully enclosed bellows protect the Y and Z axes from abrasive-garnet buildup. The X axis features dual drives and completely covered custom aluminum extrusions to protect bearing surfaces during cutting.

Flow International

Flow International

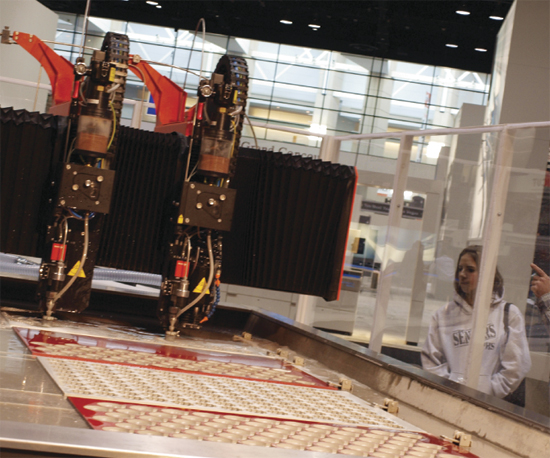

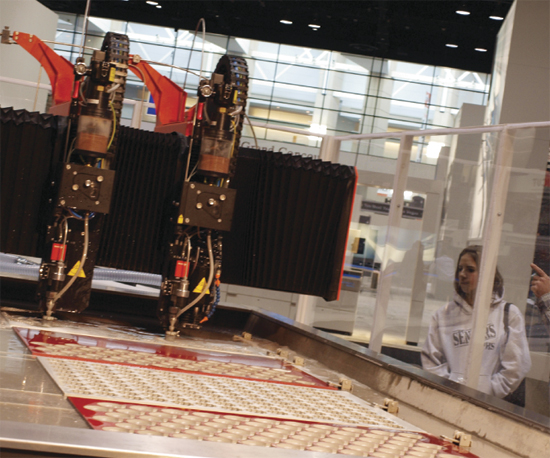

Flow International showed us its new Mach 4c waterjet-cutting machine, boasting an expandable and modular design and equipped with its new HyPlex Prime direct-drive pump. Fabricators can spec the Mach 4c to a maximum length of 48 ft., allowing them to increase the size of the cutting area as their business grows. Evident at the show was the Mach 4c’s ergonomic design, which improves operator access from all four sides, enhances workpiece visibility and allows for efficient abrasive removal.

Also on display: Flow’s Mach 2c value-priced machine designed for pure or abrasive waterjet cutting.

Bystronic

Bystronic

Bystronic introduced Fabtech visitors to its new ByJet Smart waterjet-cutting system, described as “economically priced to acquire and maintain.” Equipped with an innovative cutting bridge fitted with a linear motor, the machine can carry one or two cutting heads and offers a maximum positioning speed of 780 in./min. over a cutting area of 5 by 10 ft.

MF

See also: Hypertherm, Inc., TRUMPF Inc., Mazak Optonics Corporation, Salvagnini America, Inc., MC Machinery Systems

Technologies: Cutting

The talk of the town undoubtedly was fiber-laser technology, promising efficient, accurate and high-speed cutting of thin-gauge sheetmetal. Amada America became one of the first companies to introduce fiber technology to the world when it debuted its FOL3015AJ fiber-laser cutting machine at EuroBlech in October 2010. I watched that machine run through its paces in Germany, and joined hundreds of other Fabtech visitors in amazement

The talk of the town undoubtedly was fiber-laser technology, promising efficient, accurate and high-speed cutting of thin-gauge sheetmetal. Amada America became one of the first companies to introduce fiber technology to the world when it debuted its FOL3015AJ fiber-laser cutting machine at EuroBlech in October 2010. I watched that machine run through its paces in Germany, and joined hundreds of other Fabtech visitors in amazement  as it did its thing in Chicago. The machine featured a 4-kW laser and a three-axis linear-drive system providing 5G acceleration over a 5- by 10-ft. worktable. It promises to make quick work of most metal-alloy stock to 0.875 in., although we’re told by experts that fiber lasers provide optimum benefit, compared to CO2 lasers, at material thicknesses to about 6 mm, or ¼ in. To optimize productivity, Amada equips the machine with high-speed shuttle tables and an automatic nozzle changer—nozzle changes take 31 sec.

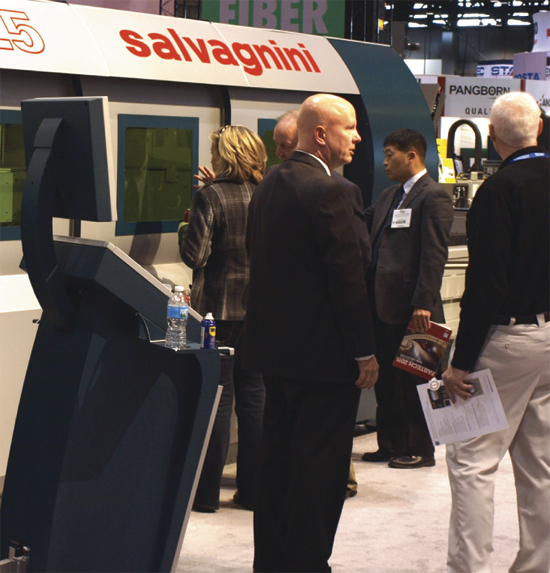

as it did its thing in Chicago. The machine featured a 4-kW laser and a three-axis linear-drive system providing 5G acceleration over a 5- by 10-ft. worktable. It promises to make quick work of most metal-alloy stock to 0.875 in., although we’re told by experts that fiber lasers provide optimum benefit, compared to CO2 lasers, at material thicknesses to about 6 mm, or ¼ in. To optimize productivity, Amada equips the machine with high-speed shuttle tables and an automatic nozzle changer—nozzle changes take 31 sec.  Fabtech marked Salvagnini’s launch of its second-generation fiber laser, the L5 (as seen on the cover of this issue of MetalForming), boasting what the company calls its “compass structure.” Also a 5G machine, the L5’s patented mechanical drive system features a pair of rotary motors that, say company officials, offers similar dynamics to those of linear motors yet consumes less than 1 kW of power when in operation. The use of rotary motors also means that the system requires a comparatively simpler structure, since they do not need dedicated cooling systems or optical scales. The L5 comes in two configurations—the L5-30 features a 2-kW laser and 5- by 10-ft. worktable, while the L5-40 features a 3-kW laser and 5- by 13-ft. worktable.

Fabtech marked Salvagnini’s launch of its second-generation fiber laser, the L5 (as seen on the cover of this issue of MetalForming), boasting what the company calls its “compass structure.” Also a 5G machine, the L5’s patented mechanical drive system features a pair of rotary motors that, say company officials, offers similar dynamics to those of linear motors yet consumes less than 1 kW of power when in operation. The use of rotary motors also means that the system requires a comparatively simpler structure, since they do not need dedicated cooling systems or optical scales. The L5 comes in two configurations—the L5-30 features a 2-kW laser and 5- by 10-ft. worktable, while the L5-40 features a 3-kW laser and 5- by 13-ft. worktable.

Among the advancements dotting the Mazak Optonics booth was, first and foremost, its Optiflex 3015 4-kW fiber-laser cutting machine. Mazak personnel explained to showgoers how it manufactures the Optiflex 3015 Fiber in an underground, eco-friendly factory with ISO-4001 certification. Further adding to its eco-friendliness, the machine offers an 80-percent reduction in generator and chiller electrical power consumption when compared to conventional laser processing, we’re told. It includes a flexible, high-speed two-pallet changer that Mazak says is 58 percent faster than previous models. And, the torch, nozzle and pallet changing can occur simultaneously to minimize noncutting time.

Among the advancements dotting the Mazak Optonics booth was, first and foremost, its Optiflex 3015 4-kW fiber-laser cutting machine. Mazak personnel explained to showgoers how it manufactures the Optiflex 3015 Fiber in an underground, eco-friendly factory with ISO-4001 certification. Further adding to its eco-friendliness, the machine offers an 80-percent reduction in generator and chiller electrical power consumption when compared to conventional laser processing, we’re told. It includes a flexible, high-speed two-pallet changer that Mazak says is 58 percent faster than previous models. And, the torch, nozzle and pallet changing can occur simultaneously to minimize noncutting time.  Ermaksan used the Fabtech stage to showcase its new Fibermak fiber-laser cutting machine, boasting of energy consumption 70 percent less than cutting with CO2 lasers, and three times the cutting speed on thin sheet. Axes are equipped with linear motors and drives that allow travel speeds to 141 m/min. and accelerations to 2 G.

Ermaksan used the Fabtech stage to showcase its new Fibermak fiber-laser cutting machine, boasting of energy consumption 70 percent less than cutting with CO2 lasers, and three times the cutting speed on thin sheet. Axes are equipped with linear motors and drives that allow travel speeds to 141 m/min. and accelerations to 2 G.  Those looking to expand beyond cutting and machining only metallic products, such as ceramics, composites, plastic, glass and stone, find waterjet cutting to be the process of choice. While discussing waterjet technology with the folks at the Mitsubishi booth at Fabtech, we learned about its new entry-level machine due to be introduced early in 2012. While not quite ready to be displayed at Fabtech, Mitsubishi personnel offer

Those looking to expand beyond cutting and machining only metallic products, such as ceramics, composites, plastic, glass and stone, find waterjet cutting to be the process of choice. While discussing waterjet technology with the folks at the Mitsubishi booth at Fabtech, we learned about its new entry-level machine due to be introduced early in 2012. While not quite ready to be displayed at Fabtech, Mitsubishi personnel offer