Hydraulic Hot-Stamping Press

March 1, 2009Comments Interlaken, Chaska, MN, now offers turnkey fully

|

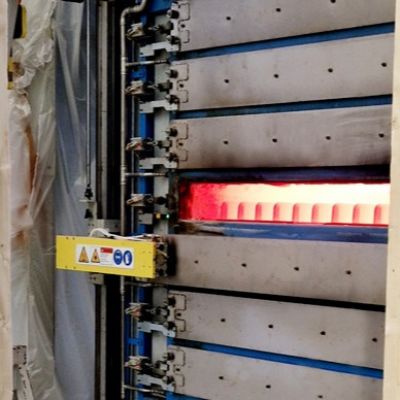

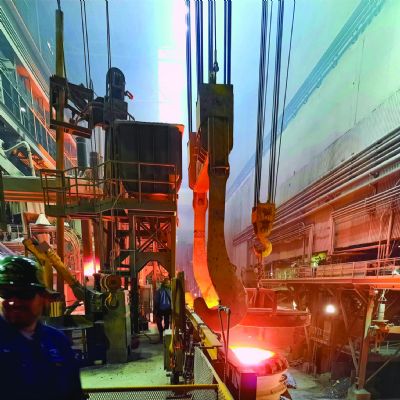

The automated hydraulic-press system can be configured to manufacture a variety of parts. With quick-change dies and tooling, the press is quickly configured to run a new part with very little downtime. Several quality-assurance features have been included in the controller to ensure proper system operation, and system alarms can be set to notify operators of changes detected in any step of the hot-stamping process.

Interlaken Technology Corp.: 952/856-4210; www.interlaken.com

Industry-Related Terms: Quenching, Run, Alloys, Blank, Die, Form, Forming, Hydraulic Press

View Glossary of Metalforming Terms

View Glossary of Metalforming Terms

See also: Interlaken Technology

Technologies: Stamping Presses