Ergonomics Appreciated

|

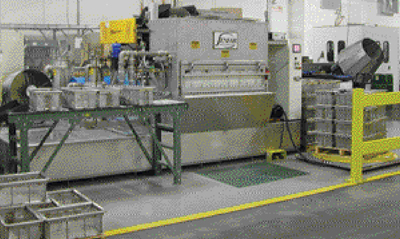

The Lean Clean 360-4 employs a process chamber constructed of 11-gauge Type 304 stainless steel, with 110-gal. capacity. Its V-shaped bottom is pitched from three sides for complete, 100 percent drainage. As described on the Jenfab website, www.jenfab.com, this is how the cleaning machine works. Wash and rinse solution tanks are located below the cleaning chamber. Fresh, filtered solution is directed at the parts at 180 gal/min. and at 50 psi through high-pressure submerged jets. Baskets full of parts rotate in the solution. The entire volume of the cleaning chamber is turned over nearly twice per minute. This fast, recirculating turnover rate scrubs the parts clean while it flushes a soil and oil, and fresh, clean solution remains constantly in contact with Highland’s stampings. Ultrasonic cleaning occurs when tiny bubbles or cavities rapidly form and collapse in the cleaning solution—referred to as cavitation. This aggressive process proves particularly useful for cleaning complex formed parts where oil and contaminants can become lodged in crevices. |

The rotating-basket cleaning system employs ergonomic, waist-high loading: Highland employees need not lower the baskets or lift them out of the cleaning chamber. Baskets rotate 360 deg. to submerge the stampings and expose all surfaces to an immersion wash and a powerful submerged spray.

The machine processes four baskets, side by side, per cycle. Its small footprint—8.5 by 9 ft.—requires minimal floor space and lends itself to a cellular configuration, and its simultaneous processing of four baskets ensures considerable throughput for its size.

|

| ITW Highland specializes in deep-draw stamping of parts for products such as oxygen sensors, hardware components, airbags and writing instruments. |

The Lean Clean 360-4 at ITW Highland meets and exceeds precision cleaning specifications thanks to its ultrasonic cleaning option. A 25-kHz piezoelectric ultrasonic resonating transducer in the process chamber uniformly disperses ultrasonic cavitation into the parts as the baskets rotate or articulate. Rotation within this ultrasonic field ensures that the full power of ultrasonic energy reaches all of the parts. Rocking in the solution offers even longer contact time with the ultrasonic action.

Installation at Highland was quick and simple, since all of utility connections are single-point. Upon spotting, minimal time is required to connect utilities. And, standard Allen Bradley Micro Logix PLC controls made start-up and programming relatively uncomplicated, reports Highland.

Cleanliness Next to Godliness for Highland’s Customers

ITW Highland manufactures a large volume of automotive components. In addition to its second-tier automotive customers, the company serves a line of commercial customers, including valve and appliance manufacturers. Specifications for cleanliness are to the particulate level for parts such as automotive fuel injectors. Typically, residual particulate extracted from a designated number of sample pieces is weighed to a customer specification. The company plans to accommodate even tighter specifications, to the micron level, in the future.

Weber, noting that ITW Highland processes an average of a half-million parts per day, says that while the new cleaning machine currently runs only one shift, Highland intends, early next year, to add a second shift to bring back inhouse some of its outsourced cleaning work. To handle the increased cleaning workload, a second Lean Clean 360 will be added to the firm’s equipment list. MF

Article submitted by Jensen Fabricating Engineers, Inc., Berlin, CT, 860/828-6516.

View Glossary of Metalforming Terms

See also: Jensen Fabricating Engineers, Inc.

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

FinishingAutomated Machinery for Grinding, Deburring and Finishing

Thursday, August 1, 2024

Lubrication

LubricationDaubert Cromwell Appoints Rodrigo Martinez Mexico Country Le...

Monday, March 18, 2024