Laser Ablation for Part Finishing

March 27, 2019Comments

Coldwater Machine Co. now offers design and build capability for laser ablation systems, which provide an alternative to traditional surface finishing. The systems can be designed for stand-alone operation or for integration into any manufacturing process that requires cleaning of parts prior to another operation.

Coldwater Machine Co. now offers design and build capability for laser ablation systems, which provide an alternative to traditional surface finishing. The systems can be designed for stand-alone operation or for integration into any manufacturing process that requires cleaning of parts prior to another operation.

Company officials offer numerous reasons for considering laser ablation. As compared to grinding, lasers create a cleaner, smoother surface by eliminating burrs and nicks without increasing surface roughness. And, compared to fluid washers, laser ablations stations typically have a smaller footprint, require fewer components, and are easier to maintain.

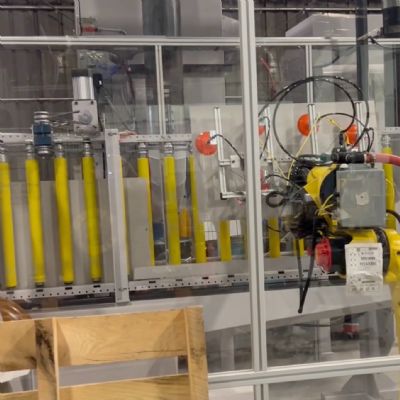

Recently, Coldwater integrated a 3 by 3-ft. laser ablation station around existing automation within a laser welding cell. Here, the components for cleaning travel on a conveyor into a Class 1 laser enclosure with glass specifically tinted for viewing of laser processes. The door then comes down to enclose the part and shield the light emitted from a 100-W laser. Situated on a servo-driven powered slide unit, the part is raised and rotated 360 deg. to ensure removal of any dust, oil, coolant and debris from all sides.

See also: Lincoln Electric Automation

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

FinishingQuick, Efficient Slag Removal

Monday, November 11, 2024

Lubrication

LubricationDaubert Cromwell Appoints Rodrigo Martinez Mexico Country Le...

Monday, March 18, 2024