Angled Flap Discs for Grinding in Hard-to-Reach Places

February 1, 2017Comments

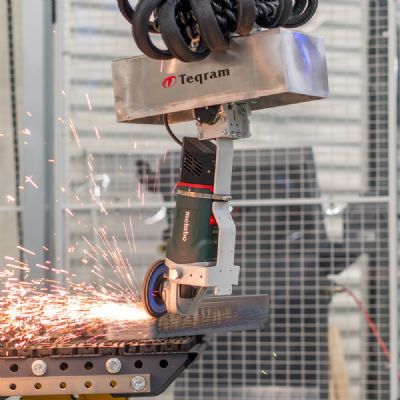

Weiler Abrasives Group, Cresco, PA, introduced a new angled flap disc to its Tiger lineup of coated abrasives, engineered to deliver aggressive grinding and long life, along with greater flexibility for grinding fillet welds, T-joints, hard-to-reach places, and for repair and rework. The discs prove ideal for grinding mild and stainless steels, aluminum alloys and other challenging materials without wearing prematurely.

Tiger Angled flap discs feature a 90-deg. angled flap design that allows operators to grind at a higher or lower angle, along with a phenolic backing that provides stability to the flaps. This combination optimizes flap-to-metal contact, resulting in optimum feel and control for the operator during grinding and finishing. In addition, the angled flaps reduce the risk of gouging the workpiece when grinding fillet welds, for a smooth finish.

Tiger Angled flap discs are available with a 7⁄8 in. arbor or with a 5⁄8 in.-11 nut for fast changeover, and with either a ceramic or zirconium abrasive. Both grain types offer a contaminant-free option for stainless-steel applications. The ceramic-alumina version features a top coat that grinds cooler to protect valuable parts, and prevents loading on softer alloys; the zirconia-alumina option features self-sharpening grains that deliver aggressive grinding and long life.

Weiler Corp.: www.weilercorp.com/tigerangled