The Solution: An Automated Conveying System

Making the move to small-batch production with plastic totes, any reduction of press uptime was deemed unacceptable by the Polaris engineering staff. Automating tote changes became the goal, and Polaris process-improvement technician Randy Osborne turned to equipment supplier TCR Integrated Stamping Systems, Wisconsin Rapids, WI, to provide a solution. TCR developed a conveyor system to count actual parts as they enter the bins, and automatically exchange full bins for empty bins without stopping the press. Several empty bins are prestaged, giving operators time to tend to other duties without interrupting production.

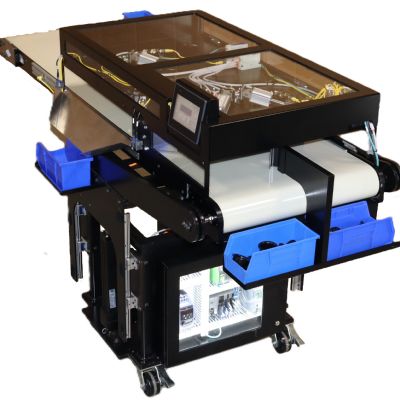

The conveying system developed by TCR can be used with any of several prepared presses at Polaris, regardless of passline height. It can handle three different bin sizes, and stamped parts no longer fall from a great height, eliminating concerns about finished parts bouncing out of the totes. And, ergonomic concerns were addressed as well, as full bins discharge onto a gravity conveyor at a comfortable work height.

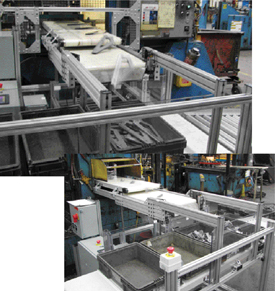

Two Conveyors, with Part Sensors

Two conveyors work together to reach into the die—an upper conveyor extends out to reach smaller tools, and can be retracted to adjust for longer dies. Sensors count actual parts as they enter the tote. Empty strokes counted during coil threading, or parts that fail to properly land on the exit conveyor, do not create an error in the parts counter.

Four empty bins are staged so the press can run untended, based on the number of parts per bin. The configuration allows Polaris, in the future, to add an automatic empty-bin loader and longer cue for the full bins, to allow more prolonged operation without operator tending.

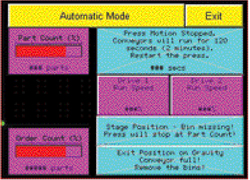

Sensors monitor the locations of empty and full bins, and the control software ensures that faults—such as no empty bin available or no place to put the next full container—will trigger the conveyor system and the press to stop.

A quick-disconnect cord allows the conveyor system to be quickly connected to any of the prepared presses. Casters allow an operator to easily move the system press to press without the use of a lift truck. The controller’s touchscreen interface employs simple commands for system setup, with screen prompts to assist with operation and troubleshooting.

Three Systems Installed

TCR produced three of the automated bin-changing systems for Polaris, all of which were installed earlier this year on 200-ton coil-fed presses—two gap-frame presses and one straightside—including Polaris’ construction of new guarding. Positive results were immediately realized.

Conveyor-system controls proved easy to use and understand. On the very first production run, a Polaris press operator ran three complete coils with 100 parts/bin without stopping production for bin changes. This provided plenty of time between press-tending responsibilities for the operator to perform other duties while the press ran—staging new coils on the coil car, handling required paperwork for shipping, and inspect parts as required. In fact, the plant realized an unexpected benefit regarding visual inspections. A Polaris operator noted that its standard sampling rate required a visual inspection of one part/hr., but, he said, “Because I did not have to constantly move bins and restart, I found that I was inspecting one part in every bin. This helps me catch problems more quickly, and reduce scrap and rework.”

Adds manufacturing supervisor Ehric Gullickson, “These systems will increase our press uptime while freeing up our operators to perform other duties.”

Stampers face new challenges every day, and innovative companies find s to improve their bottom line and keep manufacturing strong in the face of global competition. MF

See also: QC Industries, LLC, TCR-Integrated Stamping Systems

Technologies: Pressroom Automation, Sensing/Electronics/IOT