Resistance Welding Fasteners to High-Strength Steels

April 1, 2018Comments

|

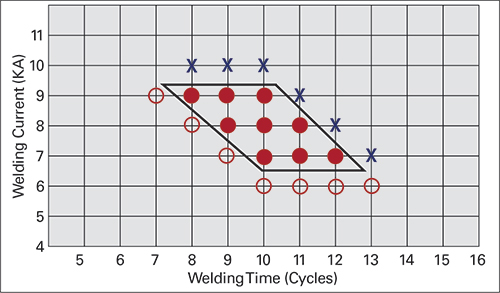

| Fig. 1—A proper weld lobe can be developed through an R&D process. The colored dots represent acceptable weld results, clear dots denote the border where weld results rest on the edge of being acceptable and X marks signify positions that fall outside of acceptable results. |

Unfortunately, we get calls like that all too often.

Resistance projection welding of fasteners has been popular for many years, and the wide plastic range of mild steel has made the process possible without much thought. However, welding fasteners to new, lightweight advanced-high-strength steels—which is not as simple and straightforward as it might appear–presents a host of difficulties.

As explained by resistance-welding expert Don DeCorte of RoMan Manufacturing, a maker of resistance-welding transformers, challenges in projection welding nuts and studs to high-strength steels are caused by in-die heattreating processes and base-metallurgy transformations. These result in increased material hardness and inconsistent martensitic surface conditions.

|

| Fig. 2—A threaded nut is welded to a high-strength-steel stamping on a rigid-framed press-type protection welder. |

“A wide difference in hardness between high-strength sheetmetal and projections on fasteners makes it difficult to forge the projections into the sheetmetal without severe expulsion and inconsistent weld strength,” says DeCorte. “Resistance-welding problems typically begin when the hardness of sheetmetal exceeds 700 MPA, and some boron and Usibor steels present even more welding challenges, since they can reach hardness levels of 1400 MPA.”

But, with welding-schedule charts not yet readily available for projection welding fasteners to high-strength steel, a careful R&D process often is needed to identify and optimize the three most important variables in resistance welding: weld force (tip pressure), weld current (secondary amperage) and weld time (duration of current flow).

In our resistance-welding seminars, we teach the concept of determining a proper “weld lobe” during the R&D stage. Numerous articles and even a book have been written on developing these lobes. Simply put, a good weld lobe graphically represents all of the welder settings that will produce customer-specified results (Fig. 1).