Differentiating Between Light- and Heavy-Duty

Since some of the respected manufacturers mentioned above also marketed light-duty models to compete with imports, it’s important to understand the differences.

When considering the remanufacture of an RW machine, look for a model with as many of these features as possible:

• Heavy-duty cast-copper secondary conductors with built-in water-cooling circuits.

|

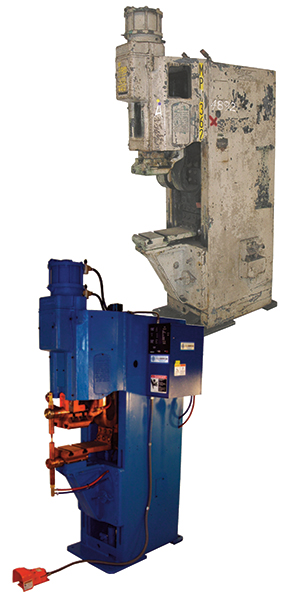

1) Select a heavy-duty machine design worth remanufacturing. 2) Disassemble the machine completely, down to the last bolt. 3) Save electrical insulation materials and non-magnetic bolts for reuse. 4) Scrap the old control, unless it’s a current model with good vendor support. 5) Sandblast and spray-paint the frame. 6) Clean all copper secondary connections and remachine mating surfaces as required for intimate contact. (See photo above.) 7) Check the transformer for short-circuited coils and internal moisture, using a Megger (mega-ohm) meter. 8) Check for clogged water-cooling lines. 9) If necessary, send the transformer to a specialized repair facility. Most electric-motor shops lack the expertise to rewind RW-machine transformers. 10) Check for proper operation of the transformer’s multistep tap switch and repair or replace as required. 11) Remachine or replace worn parts, especially in the force-delivery system of press-type and rocker-arm machines. 12) Reassemble the machine using proper electrical insulation and nonconductive bolts. 13) When reassembling secondary copper connections, apply a thin coat of copper lube or similar electrically conductive oxide inhibitor. 14) Rebuild or replace the air cylinder. Cylinders often can be replaced at relatively low cost. When rebuilding an air cylinder, use all new packings and a new cylinder wall, if required. 15) Install a new filter, regulator, lubricator and gauge. 16) Install an entirely new water-cooling system, including hoses, manifolds, water-flow indicators and a water-flow switch. 17) For good water flow to all components, run water circuits in parallel, not series. 18) Test the machine to new-machine specifications. |

• Arms, electrode holders and all other secondary conductors fabricated of copper, rather than less-conductive brass.

• Stacked-core RW transformers with adequate water-cooling circuits.

• Easily accessible transformer tap switch with six to eight steps of coarse heat regulation.

• In vertical-action press-type spot- and projection-welding machines, look for a roller-type or ball-bearing ram design; avoid the quill-type metal-to-metal rams commonly used in lower-cost machines.

• Also relative to press-type welders, look for a machine with a fast-follow-up device built into the ram, such as a die spring or diaphragm-type air cylinder.

• Other desirable features include adjustable- and retractable-stroke air cylinders.

If you can’t decide between likely candidate machines for a remanufacture project, weigh the machines being considered and select the heaviest. And, for best results, use the suggested remanufacturing steps as outlined in the sidebar.

Control Retrofits

Due to significant advances in RW process-control technology, plan to scrap old, obsolete controls and invest in a new control. And, if you’re willing to make a substantial investment to have the latest inverter-type mid-frequency direct current (MFDC) RW technology, new MFDC transformers and controls can be retrofitted to old machine frames. This single-phase AC to three-phase DC conversion can provide significant power savings, along with higher secondary currents and a more precisely controllable output.

In addition, there is a retrofit control now available that converts an existing AC RW machine to inverter technology, including integral weld monitoring and adaptive feedback. And, this retrofit package preserves the robust transformer design of a standard AC resistance welder.

Another relatively new welder control feature available: a soft-touch option that improves operator safety. MFView Glossary of Metalforming Terms

See also: T. J. Snow Company

Technologies: Welding and Joining