Robotic Welding Gives "Hit-'n-Ship" Stamper a New Look

March 1, 2015Comments

Tier One/Tier Two automotive metalformer Wellington Industries leverages its manufacturing IQ to become a prominent supplier of robotic-welded (resistance and MIG-braze) front-end modules for some of the most popular platforms.

Chris Richards, director of engineering at Wellington Industries, Belleville, MI, calls the company a ‘go-to’ stamper for side sills, A and B pillars, reinforcements and more,” noting how much takeover work that has landed at the company in recent years. The shift began during the automotive downturn, and continues today through the industry’s recovery.

“They (the Tier One companies) brought the design intelligence to the table, and we developed the manufacturing IQ needed to engineer, stamp and assemble new front-end modules,” says Richards. We’re talking supporting production of the higher-volume models.

High-Volume Assembly Provides a Makeover

Wellington operates out of a pair of side-by-side facilities in Belleville—its original 150,000-sq.-ft. stamping plant outfitted with 15 big-bed mechanical presses, and a neighboring 100,000-sq.-ft. assembly facility the firm took over in 2010. This facility is home to eight robotic-welding cells. It’s this more recently inhabited assembly plant that “represents the new look of the company,” Richards says.

The firm’s foray into high-volume assembly dates back to 2010 when, responding to a request from a Tier One supplier, it took over front-end module assembly for a popular model. To meet the required just-in-time next-day delivery requirements, Wellington installed a robotic-welding cell within an e-coating facility.

“This reduced the number of containers required from 300 to 100,” says Richards, “allowing us to be extremely competitive on the project while expediting shipments and streamlining the production/delivery process.”

Next, late in 2011, came another burgeoning program for another Tier One supplier, a takeover job that proved a perfect fit for Wellington’s goal to become a prime source for front-end modules.

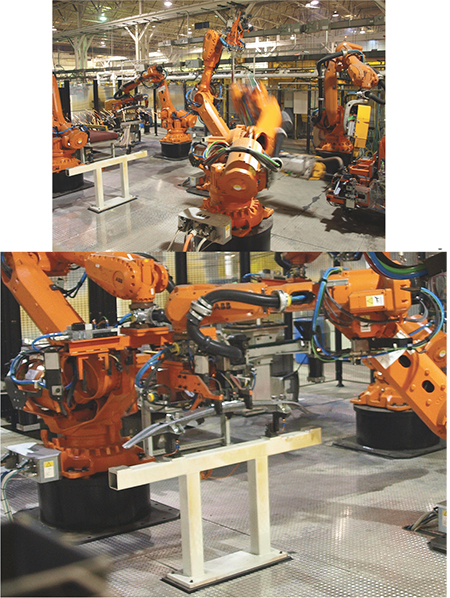

“When we gained that second front-end-module program,” says Richards, “we partnered with ABB Robotics to help us develop new robotic-welding cells rather than rely on the existing equipment used by the original supplier. We’d had previous experience with ABB on a robotic laser-trimming line working with hot-stamped roof side rails, and that gave us the confidence to use them for our first big inhouse robotic-welding project. And the rest, as they say, is history.”

A Stampede of Robotic-Welding Work

“We work to modify tolerances to best navigate process variances,” he says. “This means that in the pressroom, we have to learn to design the stamped parts to accommodate the distortion, or drift, we experience during arc welding.”

In addition to predicting (using simulation software) and adapting its metalforming processes to accommodate the heat input from arc welding, Wellington also has adopted the MIG-brazing process on certain assemblies. This process promises to deliver significantly less heat input than does traditional gas-metal-arc welding. MIG brazing, using power supplies from Fronius, employs a copper-based filler wire with a relatively low fusion temperature—typically 1600 to 2000 F—and weld current typically in the 40- to 130-A range. The relatively low process temperature—no fusion of the base material takes place—generates several benefits, including minimum distortion, less zinc vaporization and fume generation, and reduced or, in some cases, eliminated weld spatter.

Resistance Welding of Hot-Stamped Bumpers

Most recently, Wellington commissioned, in mid-2014, a five-robot assembly cell for robotic welding of bumper assemblies. Assemblies include a large hot-stamped, hat-shaped, aluminized (40 g) boron-steel bumper beam and a host of welded attachments—backing plate, brackets, nuts, etc. A lineup of nine manual pedestal resistance-welding machines feeds subassemblies into the huge ABB robotic-welding cell where five robots toil—two welding robots and three that serve as material handlers.

At the entry end of the robotic-welding cell, a turntable positioner indexes 180 deg. to swing the fixtured components within reach of a pair of spot-welding robots. These perform what amount to tack welds to hold the parts within their tight dimensional tolerances for the remaining dozens of spot welds made throughout the cell. Following this quick blast of resistance tack welds, the assemblies move to idle stations where material-handling robots swing in, pick up the subassemblies and move them through a series of stationary weld stations. This finely tuned ballet of robotic motion yields completed bumpers at a rate of more than 100/hr.

Specified equipment for the newest of Wellington’s robotic-welding cells: ABB newest models of large robots, IRB 6700 models rated to 235-kg maximum payload and boasting a reach of 2.65 m. ABB describes the seventh-generation robots as offering a 15-percent decrease in power consumption compared to previous models, along with a 20-percent reduction in total cost of ownership, double the time between service intervals and an average increase in speed/shortened cycle times of 5 percent.

“When we put the cell in, it immediately went into production,” says Richards. “We had zero learning curve, and thanks to ABB’s offline process simulation we immediately took off at 60 completed assemblies/hr. Within a few weeks, by further optimizing robot motion paths and speed/acceleration parameters, we ramped up to 100/hr., or more.”