Stamper Develops Cure for Die Roll

July 1, 2011Comments

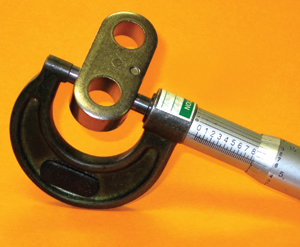

When a recent customer request-for-quote (RFQ) specified minimum die roll on pierced holes, engineers at metal-stamping company EBway Corp., Fort Lauderdale, FL, went to work developing a special stamping die to satisfy the request. The RFQ addressed a 0.409-in.-thick automotive part (left) and hex-head bolts used to fasten the part to a mating surface. Any out-of-tolerance die roll (or curved contouring on the side of the part opposite to the burr side) on the part’s pierced holes could cause the bolt heads to improperly seat as they were tightened. This could result in a misaligned assembly.

When a recent customer request-for-quote (RFQ) specified minimum die roll on pierced holes, engineers at metal-stamping company EBway Corp., Fort Lauderdale, FL, went to work developing a special stamping die to satisfy the request. The RFQ addressed a 0.409-in.-thick automotive part (left) and hex-head bolts used to fasten the part to a mating surface. Any out-of-tolerance die roll (or curved contouring on the side of the part opposite to the burr side) on the part’s pierced holes could cause the bolt heads to improperly seat as they were tightened. This could result in a misaligned assembly.

EBway designed a special die to minimize die roll and satisfy the customer spec. The technology used, which avoids any secondary machining or grinding by the customer, can be used on materials 0.060 to 0.50 in. thick.

EBway Corp.: 954/971-4911; www.ebway.com

See also: EBway LLC

Technologies: Tooling