Automated Tool Monitoring, Storage Combat Punching-Machine Downtime

March 1, 2019 Equipment that 'has your 6' goes a long way toward reliable, economical operation, without the headaches of unplanned machine stoppage.

In the just-in-time environment of modern metal fabricating, “What’s the only thing worse than downtime? Unscheduled downtime.”

|

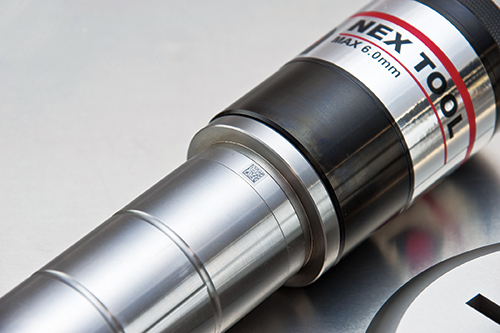

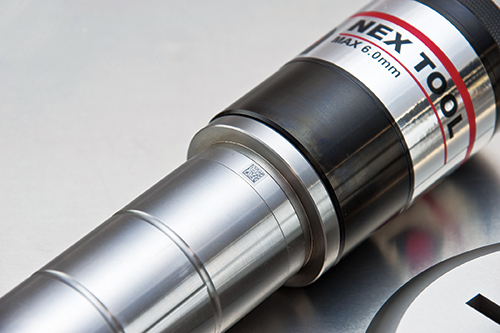

| Aiding in proactive-maintenance efforts, some of today’s punching technology incorporates capability that allows for monitoring and managing of tooling inventory. As shown here, QR marking technology captures and records all pertinent information—the tool’s location in the shop, number of times it’s been sharpened, tool height, etc. This enables tool conditions to be viewed in real time, and assigned and managed based on current shop-floor needs. |

Those wise words come from Craig Amedeo, CNC product manager for Amada America, Inc. Based at the Amada Solution Center in Schaumburg, IL, Amedeo is well-versed in CNC punch press operations, with more than three decades’ experience with the technology. In that time, he’s seen progress to where machinery can perform self-setup, run lights out given load/unload automation, and self-report issues. Automation and the evolution of Internet of Things, or IoT, have altered the fabrication landscape dramatically, and the pace seems to have quickened. Amedeo touches on some of these topics, and how they impact downtime, thus benefitting metal fabricators, in a discussion with MetalForming magazine.

“Years ago, we had no way to monitor tools on turret punch presses,” Amedeo recalls. “Fabricators looked for signs—slug pulling or burrs on parts—indicating a worn tool in need of sharpening. Fabricators reacted, because we had no way to be proactive. First-generation machines had no capability to track the number of tool hits or, perhaps, sound an alarm at 100,000 hits to sharpen a 0.5-in. round tool.”

Waiting for the creation of bad parts—that’s an unfortunate strategy for identifying tooling issues, but the other end of the spectrum also causes problems, says Amedeo.

“Counterintuitively, sharpening a tool less frequently—waiting for it to dull and start pulling slugs or slivering—ultimately shortens tool life,” he says. “Sharpening a tool every 100,000 versus every 200,000 hits means removing less material from the punch tip, and ultimately increasing overall tool life, as more material must be removed to sharpen excessively worn tools, as might be the case after 200,000 hits.”

Going Digital: New Tool for Tools

Today, punching machines take advantage of communications and automation advancements to track tooling, ensuring proper use, maintenance and replacement. Everything today seems to ride a digital trend, and punching machines are no exception. The proliferation of such technology truly allows fabricators to be proactive, not reactive.

|

| Tool information stored in a database can communicate with equipment, such as this grinding system. Upon grinding, the system updates the tool-height data of the sharpened tool, then communicates this information to a turret when the tool is scanned at the machine-loading station. “This eliminates the need for manual tool-data entry at the control, ensuring accuracy and eliminating the possibility of manual-entry error,” says Craig Amedeo, CNC product manager for Amada America, Inc. |

Historically, as Amedeo notes, punching machines had difficulty trying to maintain a real-time directory of tooling, but today’s offerings provide monitoring systems that do just that. As an example, Amedeo notes the Amada ID Tooling System (AITS) that allows for monitoring and managing turret tooling inventory. AITS uses QR marking technology to capture and record all pertinent information—the tool’s location in the shop, number of times it’s been sharpened, tool height, etc. Fabricators can obtain this information from either a shop-floor machine control or an office PC, accessed from a server, enabling all tool conditions to be viewed in real time, and assigned and managed based on current shop-floor needs.

The ability to collect and maintain accurate and actionable tool data represents a huge transition from reactive to proactive maintenance. Going one step further, what if tool data could be integrated with actual maintenance itself? Technology now exists to harvest tool data and manage the entire sharpening process, according to Amedeo, who supplies another Amada example, the ID Togu tooling sharpener.

“It automates the grinding process in many ways,” he says. “To manage the sharpening intervals, as well as the amount of material removed from the punch, the ID Togu integrates with the ID Tooling database. Upon grinding, the system updates the tool-height data of the sharpened tool, then communicates this information to the turret when the tool is scanned at the machine-loading station. This eliminates the need for manual tool-data entry at the control, ensuring accuracy and eliminating the possibility of manual-entry error.”

Video

Video