We easily can find 10 or more variables for each process input in this example, which means that 10,000 variables or more influence the process (stamping) output. But process inputs number more than four (straightening, feeding, material movement, speeds, pressures, etc.), meaning that perhaps more than one million variables can—and do—affect the process output.

We easily can find 10 or more variables for each process input in this example, which means that 10,000 variables or more influence the process (stamping) output. But process inputs number more than four (straightening, feeding, material movement, speeds, pressures, etc.), meaning that perhaps more than one million variables can—and do—affect the process output.

This makes determining a root cause to a problem seemingly impossible.

Fortunately, many metal forming processes are robust and the influence of thousands of variables do not adversely affect process output or efficiency.

Other processes, however, prove extremely sensitive to variations and perhaps only a few hundred variable combinations “open the lock” (produce desirable output). These processes require many hours or multiple shifts to get up and running properly, only to experience additional downtime after a shift change, coil change, or minor die maintenance and cleaning.

Determining root cause in a metal forming process may be impossible as process variation must be controlled and the inputs affecting poor output must be known and their effects understood.

Time Pressures Affect Problem Solving

Many manufacturers view root-cause analysis as a quality-assurance function. Therefore, they do not apply it to complex metal forming processes. Nor do they apply even simple problem-solving techniques such as five whys, fishbone diagrams and Pareto analysis to solve and document metal forming and die-related problems.

Many manufacturers view root-cause analysis as a quality-assurance function. Therefore, they do not apply it to complex metal forming processes. Nor do they apply even simple problem-solving techniques such as five whys, fishbone diagrams and Pareto analysis to solve and document metal forming and die-related problems.

In many cases, time represents the prime reason for the lack of root-cause analysis, with problem-solving steps skipped because management is impatient to obtain a quick solution. Customer demands, logistics, production-schedule changes, labor shortages and skills gaps cause organizations to operate in fire-fighting mode. Thus, potential causes often are misidentified as root cause, and the problem never goes away—problem solving becomes increasingly difficult.

Generally, people tend to see problems in a way that reflects their training. When solving a stamping-related problem, a diemaker will investigate the die. Press technicians may wonder if changes they detected in floor vibration and the sound of the press are contributing factors. A quality engineer, who recently encountered quality issues with the sheet metal supplier, may suspect a supplier quality issue.

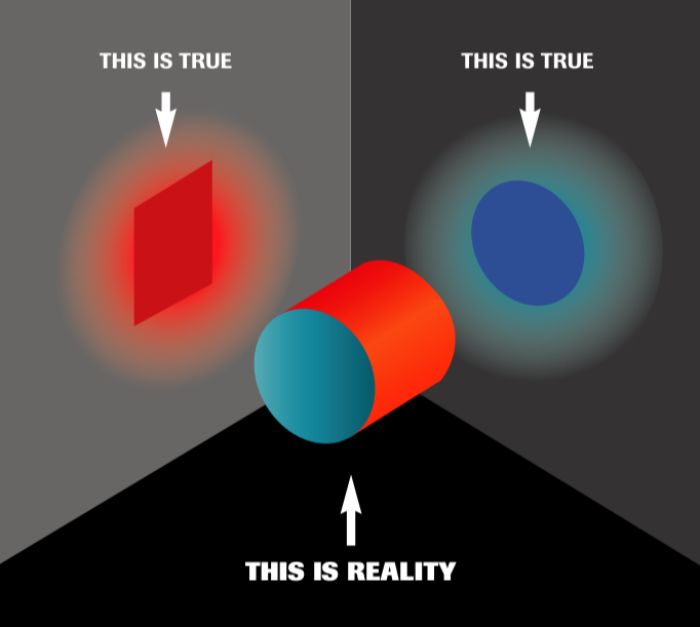

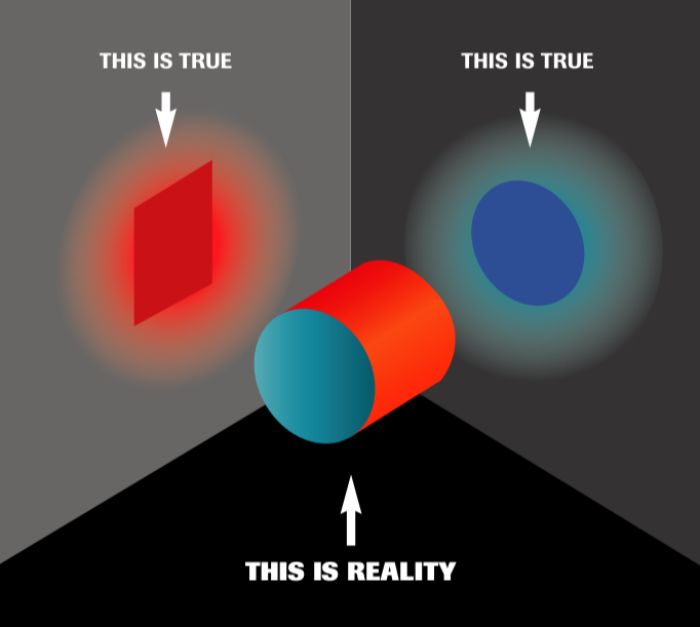

As Fig. 3 shows, individual biases influence how problems are viewed. Neither observer has a full understanding of the problem (reality), but both see the situation according to their own perspective (truths) and training.

Engage with Employees to Assess Problems

While many metal forming companies depend on automated processes and equipment, they also must rely on people to conduct successful problem solving and keep their automated processes running. Removing friction and conflict in business processes can lead to greater quantity and quality of outputs from plant operations. Not surprisingly, successful problem solving begins and ends with people.

Leveraging the passion, creativity and frustration of the affected employees is crucial to identifying what needs to be fixed and opportunities for improvement. The more people feel involved, the greater the impact of their solutions to the problems.

People closest to the problem—production employees—often have the best perspective on how a problem might be solved and recognize potential unintended consequences of proposed solutions. However, too often, production employees are viewed as possessing less knowledge and skills than a tradesperson, supervisor or engineer. They also communicate differently, without the technical savvy and jargon of the engineer and tradesperson. The danger here: Opinions and observations of production personnel may not carry as much weight as others in the organization. But, like witnesses to a car crash, they were present when the problem occurred, and they experienced what happened before and afterward. These employees possess a different type of knowledge and skill that is very valuable to the problem-solving effort.

While many companies view finding an immediate solution as the end goal, highly successful problem-solving organizations know that the end goal is a lasting impact. This means changing the mindsets, skillsets and behaviors of employees to integrate solutions into the day-to-day work environment and organizational culture. MF

Technologies: Tooling

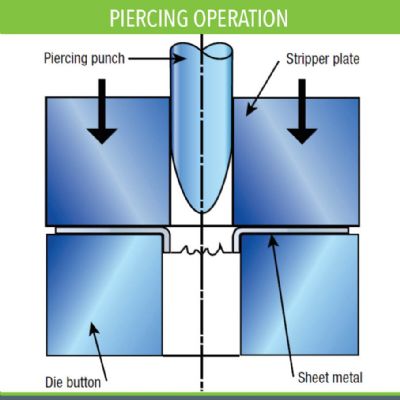

Metal forming problems can be difficult to solve. Metal forming involves a collection of process inputs that may include machine selection and its condition; tool design, construction and maintenance; lubrication type, mixing practice and application; sheet metal properties and ordering practices; environmental issues (process-related vibrations, operator inputs, deformation temperatures, thermal expansion, etc.); and other factors. Because process inputs can and do change over time—sometimes in a matter of seconds—they also are called variables. The prevailing combination of input variables interacts to produce a process output. In metal forming, the desired output is a product that meets print specifications, and that the customer will accept.

Metal forming problems can be difficult to solve. Metal forming involves a collection of process inputs that may include machine selection and its condition; tool design, construction and maintenance; lubrication type, mixing practice and application; sheet metal properties and ordering practices; environmental issues (process-related vibrations, operator inputs, deformation temperatures, thermal expansion, etc.); and other factors. Because process inputs can and do change over time—sometimes in a matter of seconds—they also are called variables. The prevailing combination of input variables interacts to produce a process output. In metal forming, the desired output is a product that meets print specifications, and that the customer will accept.

We easily can find 10 or more variables for each process input in this example, which means that 10,000 variables or more influence the process (stamping) output. But process inputs number more than four (straightening, feeding, material movement, speeds, pressures, etc.), meaning that perhaps more than one million variables can—and do—affect the process output.

We easily can find 10 or more variables for each process input in this example, which means that 10,000 variables or more influence the process (stamping) output. But process inputs number more than four (straightening, feeding, material movement, speeds, pressures, etc.), meaning that perhaps more than one million variables can—and do—affect the process output. Many manufacturers view root-cause analysis as a quality-assurance function. Therefore, they do not apply it to complex metal forming processes. Nor do they apply even simple problem-solving techniques such as five whys, fishbone diagrams and Pareto analysis to solve and document metal forming and die-related problems.

Many manufacturers view root-cause analysis as a quality-assurance function. Therefore, they do not apply it to complex metal forming processes. Nor do they apply even simple problem-solving techniques such as five whys, fishbone diagrams and Pareto analysis to solve and document metal forming and die-related problems.

Webinar

Webinar