Rotary Bending Line an Alternative to Wiping Dies

October 1, 2016Comments

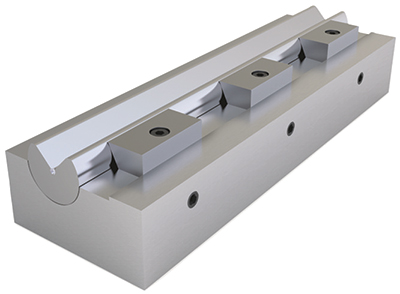

The new Posi-Bend rotary-bender line from Dayton Lamina, Dayton, OH, is designed to be less complex and less costly than wipe tooling, according to company officials. Rotary bending provides consistent metal forming without wasting material on tests and regrinds. The self-contained rotary bender cams the material without undesired distortion, sliding or marring. Other advantages noted by Dayton Lamina include the ability to bend greater than 90 deg. and to bend ultra-high-strength steel, elimination of cam tooling for producing overbends and lower tonnage than required for traditional wipe tooling.

The new Posi-Bend rotary-bender line from Dayton Lamina, Dayton, OH, is designed to be less complex and less costly than wipe tooling, according to company officials. Rotary bending provides consistent metal forming without wasting material on tests and regrinds. The self-contained rotary bender cams the material without undesired distortion, sliding or marring. Other advantages noted by Dayton Lamina include the ability to bend greater than 90 deg. and to bend ultra-high-strength steel, elimination of cam tooling for producing overbends and lower tonnage than required for traditional wipe tooling.

Standard sizes are in stock for same-day delivery, and custom orders are available with short lead times.

Dayton Lamina: www.daytonlamina.com

See also: DAYTON Lamina Corporation

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Tooling

ToolingSlug Pulling a Problem of the Past

Lou Kren Friday, May 2, 2025

CNC Punching

CNC PunchingHow Can We Resolve Our Slug-Pulling Problem?

Thomas Vacca Friday, April 25, 2025

Webinar

Webinar