QDC as Soft Automation

October 1, 2019 Quick die change (QDC), the safe, efficient and rapid movement of dies, need not be complicated, but must be present. Mark Scanlan, vice president and general manager of Germantown, WI-based PFA, Inc., shares his QDC views with MetalForming.

MetalForming: What is one of the biggest challenges facing die stamping customers today?

|

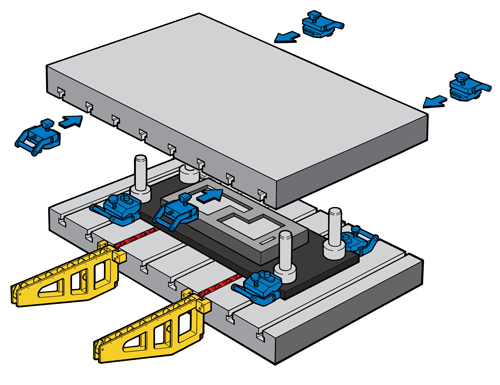

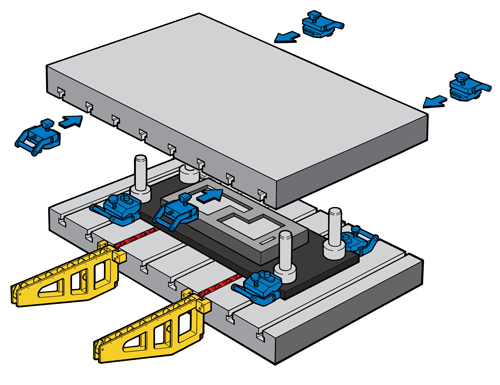

| The three basic components of a quick die change application: clamps (blue), die lifters (red) and bolster extensions (yellow). |

Scanlan: Trained and experienced staff are hard to find in the current economy. New customers say that the aging talent pool reduces the ability to push dies around even in smaller presses, raising concerns over injuries. Meanwhile, retirements limit senior-staff availability to support complex die changes. Additionally, personnel are not available to perform slower manual die changes or multiple die changes at facilities that have been slow to adopt QDC systems.

MetalForming: How can QDC practices help?

Scanlan: QDC can be thought of as another way to soft-automate production, and really should be considered as one part of improving efficiency and quality in the overall production system, while also reducing risk of injury and downtime. I call this soft automation because human experience and talent is retained in the process to maintain flexibility and responsiveness. Not all automation involves robotics or software. Automation can be anything that improves the process, removes complex manual behaviors, and replaces those actions with automatic improvements. Thinking about QDC as an automation process provides a different perspective.

MetalForming: What does QDC as soft automation look like?

Scanlan: It has to do with finding ways to maximize the talents of staff using QDC hardware, such as hydraulic clamps, die lifters, bolster extensions and related equipment designed to optimize die movement and placement. Employing QDC not only results in the desired single-minute exchange of die (SMED); more importantly, it maximizes the efficiency of staff while reducing management burden and risk. QDC practices must become so common that their absence in a manufacturing environment would be unimaginable. No one considers lifting pallets by hand; instead, we use forklifts without really thinking about them. The same needs to happen when it comes to QDC.

MetalForming: It sounds like you recommend QDC for all applications. Is that the case?

Scanlan: Certainly, some method of safely moving dies to minimize risk is necessary. On the other hand, in cases where a single die stays in the press for months, die loading can be performed safely, but slowly, and with less investment than highly efficient QDC systems. Seldom-moved dies don’t require SMED. In most production environments, however, dies move frequently with hours spent changing a single die. This provides a great opportunity for improvement and savings at many levels.

Webinar

Webinar