Punch Tip and Head Pressures

October 1, 2010Comments

My August 2010 column provided incorrect formulas for calculating punch-tip cutting pressures. The proper explanations and formulas should have appeared as follows:

The punching force is the product of the punch tip profile length (L) times the sheetmetal thickness (t) times the sheetmetal’s shear strength (st), or:

Fp = (L)(t)(st)

The shear strength for mild steel is approximately 70 percent of its ultimate tensile strength, aluminum is about 50 percent and stainless steel is about 90 percent. Shear strengths also can vary significantly within the same material type. For example, the shear strengths for copper alloys have been reported to be between 50 and 90 percent of their ultimate tensile strength, depending on the alloy.

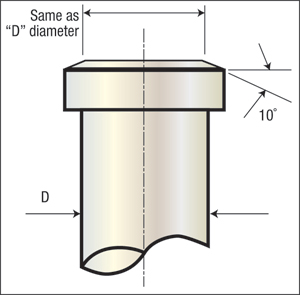

After punching force (Fp) is known, the tip pressure (Pt) can be calculated. For a standard shoulder punch, Pt is equal to the punching force divided by the cross-sectional area (A) of the punch tip:

Pt = Fp / [(p)(½d)2]

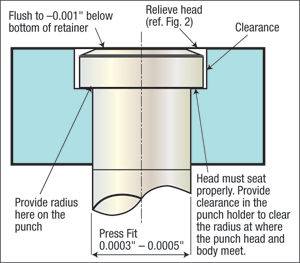

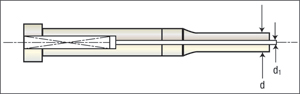

If the punch has a spring elector pin, the

|

| Fig. 1 |

Pt = Fp / [(p)(½d)2 – (½d1)2]

For those that tried to use the formula from my August column—only to find yourselves thoroughly frustrated—I apologize for the error.

I received several e-mails from readers who were not having problems with punch-tip breakage, but instead were experiencing punch-head breakage. To solve punch-head breakage problems, we must first understand why punch heads break.

Causes for BreakageThere are two main causes for head breakage: high impact force and high snapthrough forces. Impact failure results from excessive loading, which literally crushes the head. This type of failure usually occurs when the cutting clearance is tight and/or the part material is hard or thick. Conversely, snapthrough failures occur when there is a sudden unloading of pressure on the punch. This phenomenon is associated with increased punch-to-die clearance and with high-strength materials.

Other factors that contribute to head breakage are punch pumping, due to poor fitup of the punch body to the punch holder, and high-hardness backing plates.