Ag Stamper Takes Control of Part Flatness

September 1, 2009Comments

With stamping and assembly work for the agricultural industry now accounting for more than half of its production schedule, GMP Metal Products counts on EDI, automation, QDC and other lean-manufacturing tools to efficiently schedule and produce more than 700 different part numbers.

Ag business is still strong, and is dominating the product mix at contract manufacturer GMP Metal Products, St. Louis, MO, a supplier of stampings, fabricated-metal parts

and assemblies. The 220,000-sq.-ft. facility houses 70 stamping presses, to 1500-ton capacity, as well as equipment for laser-beam blanking and cutting, sheet and plate fabrication, robotic welding, and finishing. In addition to the Ag industry, GMP also supplies the construction and defense industries, and operates a second manufacturing facility in Tennessee.

GMP operates 70 stamping presses to produce a variety of Ag parts, from precise and close-tolerance transmission parts to large deep-drawn parts formed on this 1500-ton transfer press.

For 20 years, GMP has specialized in the stamping of transmission separator plates and brake and clutch plates for the Ag industry, and continues to invest in new metalforming technology and fine-tune its processes to improve quality, productivity, and—of course—reduce costs for its customers.

“We’ve gone through a crash course to become more organized, install 5S practices, upgrade our building and equipment, and institute Six Sigma training,” says GMP engineering manager Bob Mallmann, “including executive-level training and blackbelt training for a few people. And, with the addition of new press controls on a few of our presses, a focus on quick-die-change practices and other improvements, we’ve been able to exceed customer expectations for quality and delivery, while meeting cost-reduction targets.”

Straight Edges, Flat Surfaces

GMP processes some 700 part numbers just for its Ag business, many of the part numbers comprising transmission separator plates of varying different sizes and designs. Its use of EDI to communicate is critical to successful production planning, says Mallmann, to keep up with order changes.

“We receive changes every day,” he says, “and a major download weekly. We use that information for order entry and feed the orders through our ERP system (TCM, from WorkWise, Inc., Milwaukee, WI) to initiate raw-material planning and production scheduling.”

Transmission separator plates are of a modified Type 1035 steel (Rc 20-28 hardness), 0.068-in. thick and typically 10- to 20-in. dia., although the firm does stamp a much smaller plate—5-in. dia. —that it ships to an assembly plant in China.

“The customer can’t purchase steel in China to the level of quality we can here,” says Mallmann. “So, our customer assembling the transmissions in China purchases stamped parts from us here in St. Louis.”

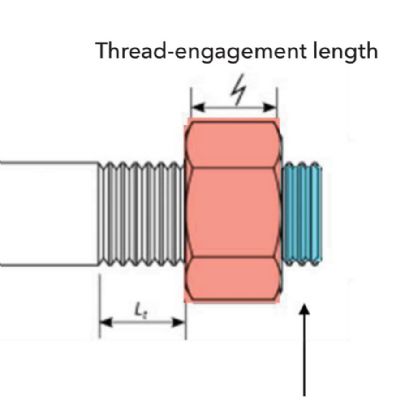

“In most cases, we use compound dies for this product line to gain optimum control over flatness,” says Mallmann, “since the die cuts all of the surfaces in one stroke. But we still have to run the stampings through secondary processes. The tangs on the outside edge of the separator plates are specified with critical edge conditions, requiring a secondary shaving operation to straighten the edges. Then we feed the parts through a rotary deburring operation and into a series of levelers (straighteners from Bruderer) to attain the required flatness in two directions.”

The compound die employs an upper punch that cuts the plate OD and also acts as the die to knock out the center hole of the blank. A punch below the stamping works the ID. GMP stocks 40 different dies for the plates in various styles and sizes, and changes dies an average of two times per shift; the press runs at 20 to 25 strokes/min.

Podcast

Podcast