Improved Visibility Brings Plenty of Surprises

Wiegel notes that his team was surprised at some of the issues that became low-hanging fruit when it came to completely grasping the various causes of unscheduled press downtime. While he expected to find that maintenance-related issues were leading to downtime—slug marks, for example—instead it was more of the procedural things that had press operators struggling. Among them, according to the new downtime codes his team put into place with ShopFloorConnect: timely staging of coils, tooling and packaging equipment and additional labor. A good lesson in 5S strategy and implementation, he says, was just what the doctor ordered in order to drive down inefficiencies.

“We also attacked our die changes—not only setup of new tools but also the process used to remove dies from our presses,” says Wiegel. “We found that we were using 130 different tools out on the shop floor, which really complicated our processes and led to inefficiencies. We have since reduced that to 35 standard tools. We also added shadow boards at every press and color-coded the tools to ensure that they remain at their assigned press.

“We also enhanced our kanban system for packaging,” Wiegel continues, “to address another downtime issue identified by ShopFloorConnect. This ensures that we keep the proper min-max levels of boxes, skids and interleaf paper at each press, so that our operators don’t have to leave the press and head out into the warehouse in search of packaging materials.”

Wiegel is Watching, Via Waterfall Alerts

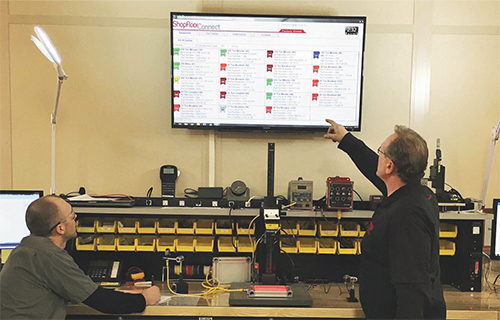

Plant-wide, everyone now knows how the company is doing in regard to OEE and changeover times. Wiegel’s managers send out daily, weekly and monthly updates that track OEE and changeover times for every press and tool. Reports track tasks that make up the complete changeover process, from last part off to first part off, including die removal, die setup, setup of scrap bins, coil feeds, conveyors and related equipment, and first-piece inspection and approval. Knowing that the data are available and shared, Wiegel says, drives home the notion that management requires plant-floor ownership of process improvement, and personal responsibility for the company’s efficiency.

Add to that the fact that employees now know that Wiegel is watching closely. He set up a waterfall alert system that, as the saying goes, has the buck stopping at his desk. For every production and changeover task, the company has assigned a reasonable time window for it to be accomplished.

If, for example, an operator indicates in ShopFloorConnect that his press is down because he is waiting for coil stock, an e-mail goes out to all of the material handlers identifying them of the need. After 5 min. (“I expect material to arrive at the press within 5 min. of the call,” Wiegel says), an e-mail goes out to alert the production manager. A 10-min. delay triggers an e-mail alert to the plant manager. And, after 20 min. Wiegel receives an e-mail alert, which sends him out to the shop floor.Tracking Tool Performance, Too

In addition to attacking OEE and changeover times, WTW also uses ShopFloorConnect to track the performance of individual tools. It tracks the number of hits between maintenance cycles and compares the data to a standard developed for each tool, to not only ensure that it’s getting the predicted life from each tool but also to help prompt maintenance scheduling.

“When new tools enter production,” says Wiegel, “we can go into ShopFloorConnect and set the limits based on how we predict they’ll perform. Then, once the tool has run for a while, we can adjust those expectations accordingly.”

Managers also have access to quick color-coded status reports for each tool—the tool status turns yellow on the display when it’s approaching its hit limit and red when the tool needs to be pulled for maintenance. “Or, a red indicator might just warn our production people to pay extra-close attention to the performance of that tool,” says Wiegel. MF

See also: Wintriss Controls Group LLC, ShopFloorConnect by Wintriss

Technologies: Management, Pressroom Automation, Stamping Presses