Testing the Concept

Tenere’s goal: to pursue a growth strategy that involves different layers of simultaneous investment, optimizing performance with its existing equipment and footprint while adding new equipment and facilities to extend capabilities and capacity. Incremental investments in controls and sensors help the firm drive performance and customer satisfaction.

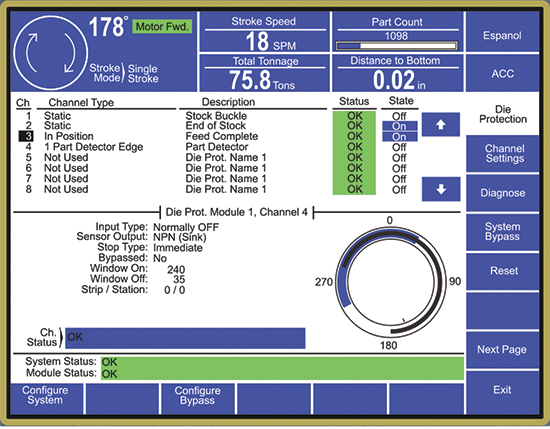

The first press selected for implementing the new controls was one of the busiest in a building full of busy presses. TCR installed a Link Systems’ 5100 AMC, (Automation Machine Control) to the press, with 16 channels of die protection, 16 programmable-limit switches, a high-end tonnage monitor and communication for the servo feeds in use.

“This gave Tenere capacity for near-term needs,” says Wenzel, “but we knew the equipment was scalable so it could add even more capacity as the die-protection program took off. It was considering the use of analog measuring sensors, as well as investigating servo-press technology. The Link control supports both of those future anticipated needs.”

In addition, discussions with Tenere’s production manager and maintenance manager revealed a need for more-efficient scrap removal and die lubrication. So, TCR added a Mayfran Shuffle Drive press-mounted scrap system to the project, and an Industrial Innovations’ spray system for die lubrication.

The Link process control mistake-proofs other parts of the production system, not just the tooling. For example, shown here is a sensor monitoring motion of the scrap system’s moving crossbar.

Mistake-Proofing Throughout

In addition to using the more sophisticated die-protection capabilities of the process control to protect the tool, TCR used the Link control to develop a more integrated production system. The goal: mistake-proof other parts of the process beyond the tool itself.

“Part-out conveyors and the Mayfran scrap system now start automatically when the operator starts the press,” Wenzel says. “Equally important, sensors monitor the scrap system, not easily seen by the operator, to ensure it runs when it’s supposed to and stops the press if the shuffle stops.”

In addition to starting automatically, saving the operator’s time, the conveyors also stop automatically when the press has been idle for more than one minute. This saves energy and reduces maintenance costs caused by systems running needlessly.

Results

Before installing the new equipment, the press ran with two operators—one handling parts and the other watching for problems in the tooling. Die crashes occurred regularly, causing production delays and overtime for repairs and for production to catch up. Now, one operator mans the press to handle the parts, hourly production has doubled and we’ve not had a single crash. It has been a major success.

Adds Tenere vice president and COO Jon Fisk:

“The new equipment fits perfectly into our lean-manufacturing goals by eliminating downtime, and increasing uptime and reliability. Elimination of crashes has led to consistent on-time deliveries without added costs.”Fisk immediately approved the installation of the equipment on three more of the firm’s busiest presses.

“Three more systems received the same upgrades,” Fisk continues. “The results were consistent with the test. Production output increased 60 to 100 percent on most jobs. Our setup times also dropped by 20 percent. Output on one job in particular —a large delicate part—actually increased from 700 parts/shift to more than 2900 parts/shift. That increase of more than 400 percent was not common, but it was not unique.” MF

Article submitted by TCR Integrated Stamping Systems, Wisconsin Rapids, WI; 800/676-2240; www.tcr-inc.com.

See also: Link Systems, TCR-Integrated Stamping Systems, Mayfran International, Inc., Aida-America Corp.

Technologies: Pressroom Automation, Sensing/Electronics/IOT, Stamping Presses