Mechanical Solutions

October 23, 2020Comments

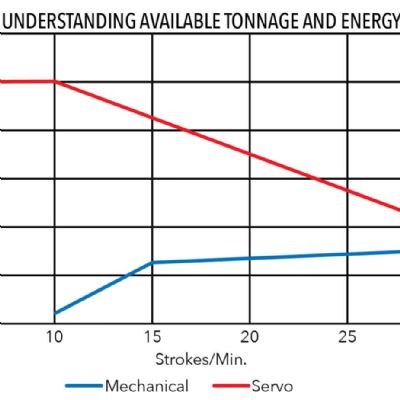

With saturated promotions surrounding servo technology, press manufacturers tend to neglect the simple fact that mechanical technology is still relevant to current industry trends and, in some cases, can prove to be a better investment for metal formers. That is why Simpac is proud to showcase our top mechanical presses.

The truth is, mechanical presses are highly recommended for the ever-growing EV market (aluminum and high-strength steel) with proven capabilities to handle battery production as well as other general stamping requirements.

“Simpac enjoys working closely with our customer base and finding optimal solutions for their specific needs,” states Stephan Robertson, general manager/VP of sales & operations at Simpac America. “We pride ourselves on producing flexible equipment that can cater to various products – not just a one-time sale of highly expensive technology like servomechanical presses.”

CS Series

CS Series

- Press Capacity: 39-340 U.S. tons

- Part Size: small

- Drive Concept: crank

- Applications: cutting, stamping, bending, embossing and forming

Simpac’s CS Series is ideal for the production of small parts. The C-shape provides great accessibility to the die space and is suitable for manual work or automated production processes. The compact design requires a small footprint and no foundation work, ensuring great accessibility for maintenance. The series can operate as a single press or press line with transfer, shuttle, or robot automation. The CS Series can be used for EV battery cell production (quadratic and cylindrical cases).

MC Series

MC Series

- Press Capacity: 340-1125 U.S. tons

- Part Size: medium

- Drive Concept: crank

- Applications: blanking, stamping, bending, and embossing

Simpac’s MC Series is optimized for a wide range of medium-sized parts. The compact design requires little floor space and no foundation for presses below 450 U.S. tons. The series can be installed as a single press in progressive or transfer mode or as a fully automated press line. The MC Series can be used for EV battery cell and module production (quadratic/quadratic cylindrical cases, cell covers, module plates, mono frames, and cooling pins).

DTE Series

DTE Series

- Press Capacity: 900-2800 U.S. tons

- Part Size: large

- Drive Concept: mechanical

- Applications: cutting, blanking, embossing, and forming

Simpac’s DTE Series is ideal for flat and semi-flat parts due to its sinusoidal slide motion curve. Presses are available in tie-rod design and are connected to a rigid frame via hydraulically pre-stressed tie-rods. The series can be installed as a single press in progressive or transfer mode or as a fully automated press line. The DTE Series can be used for EV battery pack production (outer cases and cooling plates).