Software Supports a Powder Quality-Management System

October 20, 2016Comments

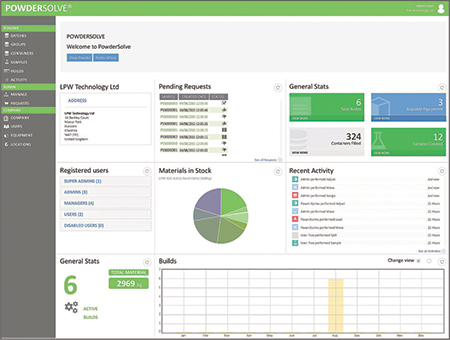

As the additive-manufacturing (AM) industry moves toward the manufacture of demanding medical and aerospace components, the need to maintain traceability throughout the full lifecycle of the powder is becoming critical. To meet this demand, LPW Technology Inc., Pittsburgh, PA, has developed its total powder management (TPM) solution, based on its Powdersolve quality-management software. Applicable to laser and electron-beam AM systems, the software provides a comprehensive understanding of what is happening to the powder, starting with goods inwards and, through repeated use on an AM machine, to full component traceability.

As the additive-manufacturing (AM) industry moves toward the manufacture of demanding medical and aerospace components, the need to maintain traceability throughout the full lifecycle of the powder is becoming critical. To meet this demand, LPW Technology Inc., Pittsburgh, PA, has developed its total powder management (TPM) solution, based on its Powdersolve quality-management software. Applicable to laser and electron-beam AM systems, the software provides a comprehensive understanding of what is happening to the powder, starting with goods inwards and, through repeated use on an AM machine, to full component traceability.

Controlling powder is the smart way to increase productivity, reduce costs and optimize stock levels. The cost of scrapping a final component due to porosity or composition issues, which often can be traced back to the powder, can be considerable in terms of wasted powder, and time.

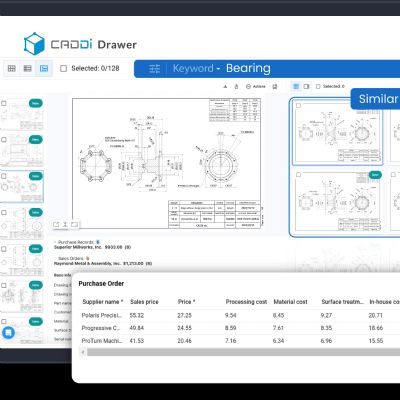

Powdersolve manages all of the information related to powder–specification control, sizing, composition, storage location, quantity, the number of times the powder has been used and the other powder batches with which it has been blended. The software provides a clear overview of the status of the AM machines, powder-stock levels, and operator and build activity. Using its analytical and reporting tools, powder degradation can be monitored and the potential life of the powder predicted as it moves out of specification.

Powdersolve also automatically generates powder and component documentation and reports, and supports the printing of labels for components, powder samples and powder storage containers. An interactive flow chart tracks chemical and mechanical test data.