New CAD/CAM Software Promises Time Savings in Roughing Operations

July 1, 2016Comments

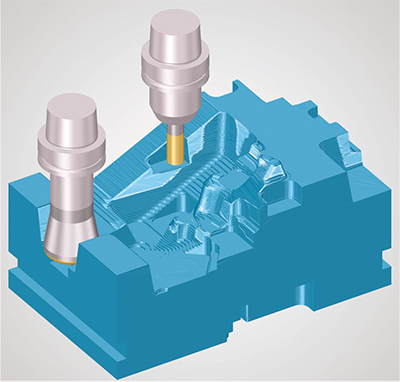

Tebis America, Troy, MI, has launched Version 4.0 Release 2 of its CAD/CAM software, especially well-suited to the rough machining of deep cavities and for hard-material machining. During roughing, the depth of cut and the best utilization of cutting data ensure fast and cost-effective manufacturing while keeping tool costs low. The tool path automatically adapts to the geometry without full-width machining. The integrated re-roughing counteracts the formation of larger steps in steep boundary areas. These areas can be machined from bottom to top with a smaller depth of cut.

Tebis America, Troy, MI, has launched Version 4.0 Release 2 of its CAD/CAM software, especially well-suited to the rough machining of deep cavities and for hard-material machining. During roughing, the depth of cut and the best utilization of cutting data ensure fast and cost-effective manufacturing while keeping tool costs low. The tool path automatically adapts to the geometry without full-width machining. The integrated re-roughing counteracts the formation of larger steps in steep boundary areas. These areas can be machined from bottom to top with a smaller depth of cut.

“The best way to machine a component depends on a wide range of factors,” explains Helmut Vergin, Tebis product manager. “These include the geometry, material and available tools and machines. Technology parameters such as cutting data and feed rates must be adapted according to the machining.”

Tebis America: www.tebis.com

See also: Tebis America, Inc.

Technologies: Software