Sheetmetal CAD/CAM Software Updated to Improve Material Utilization

October 1, 2008Comments

Radan, represented in the United States by Planit Group, Forest Lake, MN, has launched Radan 2009 R1, its sheetmetal CAD/CAM system that now includes a number of new features to further improve material utilization and enhance productivity and efficiency. Upgrades include common-line cutting on a part-by-part basis rather than whole sheet, benefiting manufacturers of precise profiled parts for assembly or tight-tolerance fabrication.

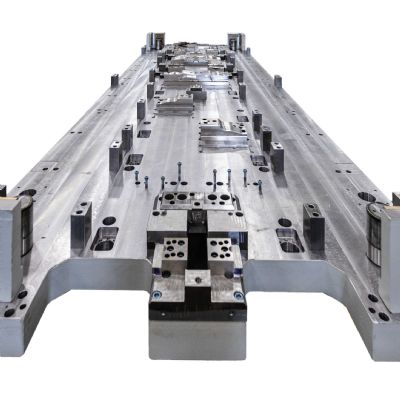

A new Edit Punch Tool feature maximizes punching-machine efficiency by finding and replacing tools used on a part. If a tool is damaged or in use elsewhere, this feature automatically finds and replaces it with the selected alternate tool. Additionally, users can quickly edit punch-tool overlaps to either improve efficiency or even create or adjust micro-joints.

A new user interface for the machine configuration editor eases system setup while allowing machine parameters to be adjusted safely and accurately. The new interface also allows the end user to adjust the various times each operation takes on a specific machine, resulting in more accurate run-time estimates.

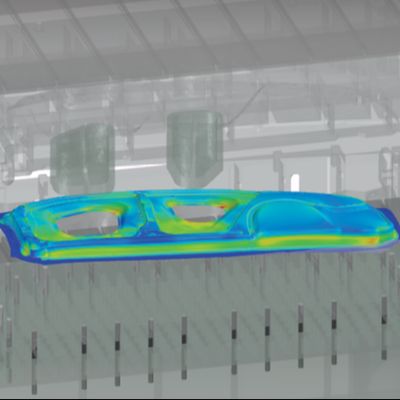

New functionality and improvements to existing nesting capabilities further improve material utilization.