Sculptured Die Face Addresses the needs of Cost Estimation, Process Planning

July 1, 2015Comments

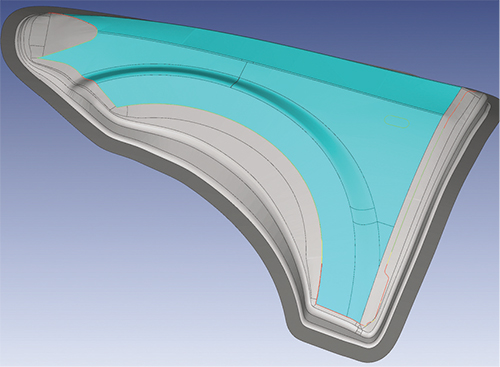

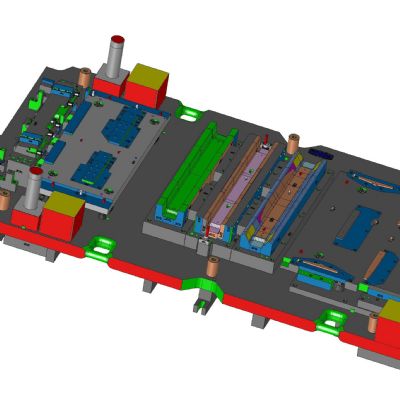

Forming Technologies Inc. (FTI), Burlington, Ontario, Canada, has released FormingSuite Sculptured Die Face (SDF) to address the needs of cost estimation, process planning and metalforming simulation. The software provides a free-form approach to creating and morphing addendum geometry, resulting in a fast, flexible and visual approach to die-face design.

- Improving the accuracy of material cost estimates by accurately considering the process geometry (including addendum) rather than just the part shape;

- Providing more detailed information to process planners responsible for identifying die size, forming and trimming operations, press tonnage and tooling costs; and

- Providing the necessary geometry to run accurate virtual die tryouts.

Designers can develop full draw developments, die faces and first-form geometry in minutes without the limitations of section lines and the difficulties associated with creating complex transition geometry in CAD systems. Fully interactive editing tools enable users to adjust and refine addendum geometry with ease, taking the user from concept to complete draw development in seconds.

SDF greatly simplifies the work involved in positioning and attaching double- and multi-attached parts, creating, editing and evaluating fully developable curved binder geometry, controlling the depth of draw, defining addendum shape, and creating fully surfaced draw developments.

Forming Technologies Inc.: www.forming.com

See also: Hexagon Manufacturing Intelligence