Metalforming Simulation Solution from Quick Die Design to Process Validation

October 1, 2016Comments

ESI Group

Booth C11122

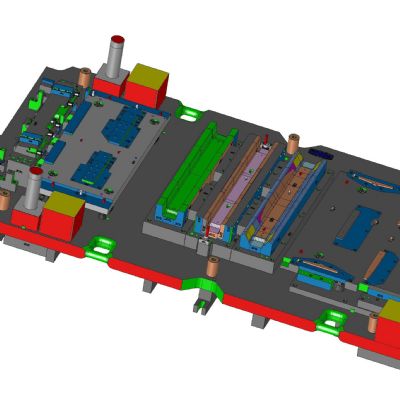

ESI Group will demonstrate its die-face design and metalforming-simulation solution PamStamp, which allows engineers to design, optimize and verify metalforming processes on their computer. The software covers cold, warm and hot sheetmetal- and tube-forming processes, and patched and tailored blanks. It finds use in numerous industries, including automotive, aerospace, electronics and appliance.

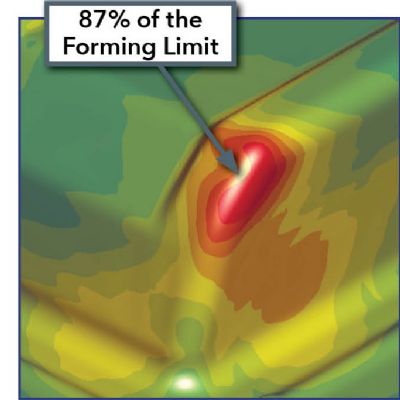

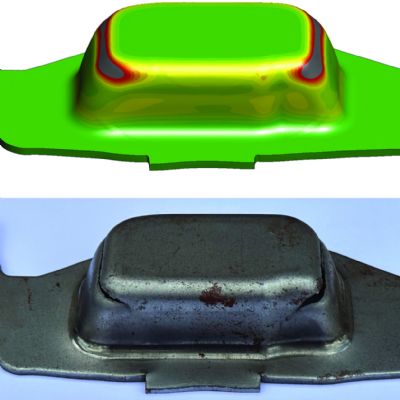

At the quoting stage, users can determine blank outlines and optimum nesting for material-cost estimation, and can quickly develop draw dies. In the feasibility phase, die designers can model tool surfaces based on B-spline geometry, and engineer a successful forming process without cracks and wrinkles, to specifications.

Operations supported include hemming, trim development and trim-line and blank-shape optimization. In the validation phase, engineers can precisely estimate springback, compensate the dies in the drawing operation or across multi operations, and detect and visualize cosmetic defects just as they would appear on the shop floor.

www.esi-group.com/pam-stampView Glossary of Metalforming Terms

See also: ESI North America

Technologies: Software