Enhanced CAD/CAM Software Improves Surface Finish in High-Speed Applications

January 1, 2015Comments

Tebis America, Troy, MI, has released Version 3.5 R8 of its CAD/CAM software, with features promising to further increase machining volumes and cutting speeds for roughing as well as finish-milling applications. Further, new point-distribution functionality is said to improve surface quality in high-speed machining, and the release also includes newly developed probe geometry.

Tebis America, Troy, MI, has released Version 3.5 R8 of its CAD/CAM software, with features promising to further increase machining volumes and cutting speeds for roughing as well as finish-milling applications. Further, new point-distribution functionality is said to improve surface quality in high-speed machining, and the release also includes newly developed probe geometry.

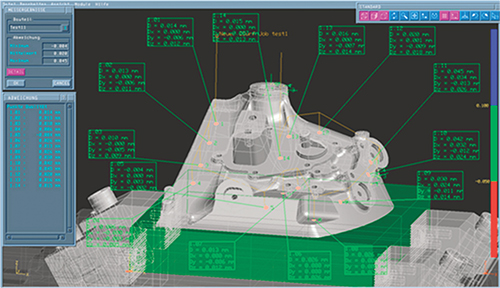

Tebis Version 3.5 R8 supports all high-speed and high-feed milling cutters with specific geometries and precisely offsets their contours. Thanks to a new measuring function, measuring paths can be created with the same methods as tool paths, using the same automation functions. A measuring probe determines the quality of the manufactured components directly at the machine. The machine controller displays any deviations from the target so they can be corrected immediately.

Lastly, Tebis Version R8 adds the ability to mill with 3D radius correction, to compensate for tool wear. Any deviation from the target is calculated with the new functions for direct measuring at the machine. For radius correction, Tebis then adds additional information to the calculated tool paths to be evaluated by the machine controllers.

www.tebis.com

See also: Tebis America, Inc.

Technologies: Software

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Software

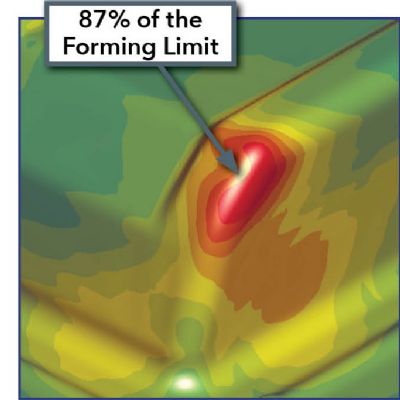

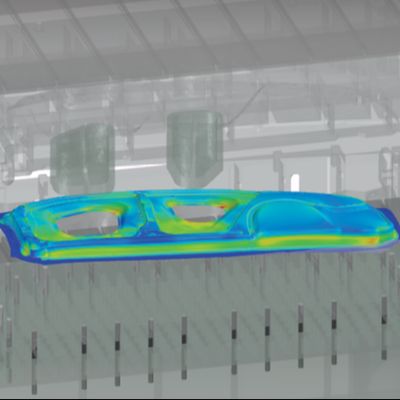

SoftwareIntuitive Automotive-Stamping Simulation

Tuesday, April 29, 2025

Materials

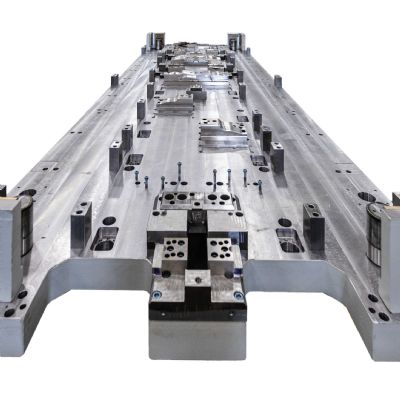

MaterialsTooling Up for AHSS: Know the Material, Mind the Simulation

Lou Kren Tuesday, April 1, 2025