CAD-Embedded Motion Simulation Helps Die Designers Slash Lead Times and Optimize SPM

October 6, 2021Comments

Longterm Technology Services (LTS), London, Ontario, Canada,

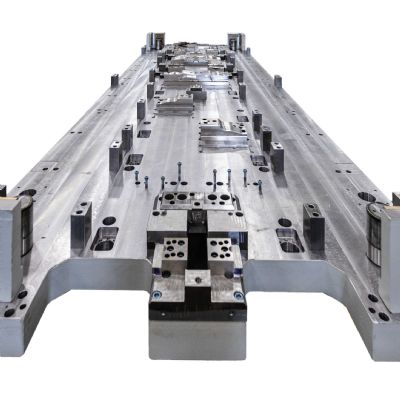

has released the latest version of its Dynmik Design for Die add-on for Siemens

NX CAD software. Powered by the Mach 3 progressive-die design package, the

software add-on helps die designers optimize press stroke rate and reduce

design-validation time reportedly by as much as 80 percent.

Longterm Technology Services (LTS), London, Ontario, Canada,

has released the latest version of its Dynmik Design for Die add-on for Siemens

NX CAD software. Powered by the Mach 3 progressive-die design package, the

software add-on helps die designers optimize press stroke rate and reduce

design-validation time reportedly by as much as 80 percent.

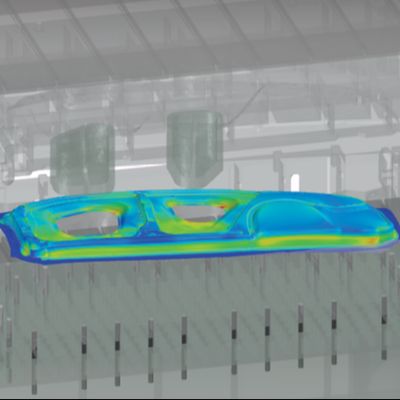

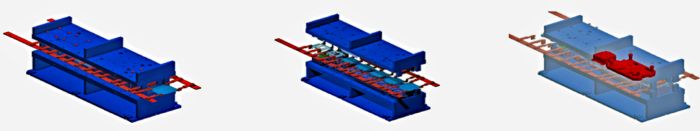

This new release, say company officials, comes in response to demand from users for the ability to set minimum zones of clearance between components once the tool is put in motion. If the die design violates any clearance requirements, including hard collisions, the software will alert the designer and suggest steps for remediation.

“The real key to this software is the perfect balance between accuracy and efficiency,” says LTS director of sales Phil Glennie. “Companies reviewing and validating die designs face unprecedented pressure to approve complex designs quickly, and this software allows them to do that with confidence.”

One of the most significant changes made to the software this year is the introduction of an SPM-optimization module, which allows designers to enter press parameters and simulate press motion to determine maximum strokes per minute. The release also allows users to run motion simulation with 10 times more power when validating complex or precise motions. Designers can use the software to easily visualize motion curves around components and duplicate existing defined components with all motion parameters and define different geometries. This helps divide components with numerous geometries into smaller segments for receiving more manageable collision-checking results downstream.

See also: Longterm Technology Services Inc.

Technologies: Software