AutoForm Enhances its Software for Design and Simulation of Tube-Forming Processes

March 17, 2022Comments

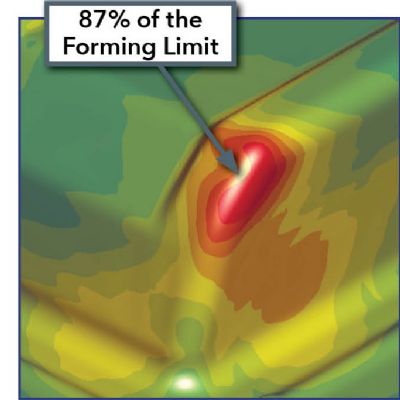

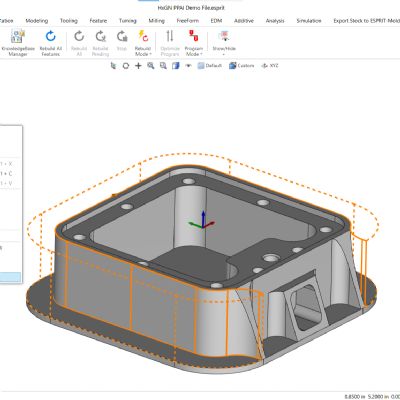

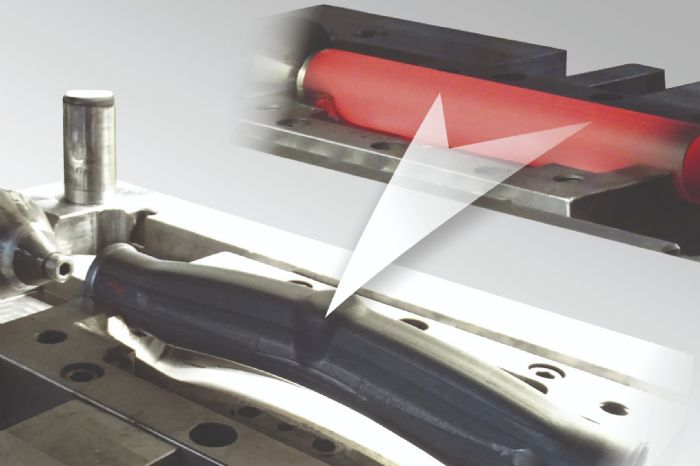

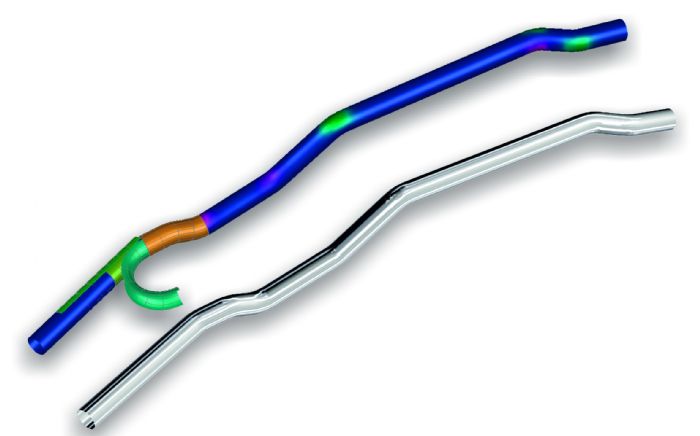

AutoForm Engineering GmbH announced the introduction of new functionality

for its TubeXpert software, developed to support tube bending, forming and

hydroforming processes. The new version features a completely new solver that includes

new material laws, enhances contact between the tube and tooling, and provides

improved meshing capability, say company representatives.

AutoForm Engineering GmbH announced the introduction of new functionality

for its TubeXpert software, developed to support tube bending, forming and

hydroforming processes. The new version features a completely new solver that includes

new material laws, enhances contact between the tube and tooling, and provides

improved meshing capability, say company representatives.

In addition, AutoForm TubeXpert now supports hot tube

forming processes including hot metal gas forming, as well as direct and indirect

hot tube forming processes. The enriched material library includes aluminum,

stainless steel, manganese-boron steels and titanium alloys applicable for hot

forming.

In addition, AutoForm TubeXpert now supports hot tube

forming processes including hot metal gas forming, as well as direct and indirect

hot tube forming processes. The enriched material library includes aluminum,

stainless steel, manganese-boron steels and titanium alloys applicable for hot

forming.

See also: AutoForm Engineering USA, Inc.

Technologies: Software