Optimized Design Yields Complex Bracket

February 10, 2017Comments

This design could not have been created with conventional manufacturing methods. Instead, the success of the finished part is due to the application of Altair’s lattice-based optimization software; Materialise’s Magics, 3-matic and Build Processor software programs; and advanced settings of the Renishaw metal-AM system.

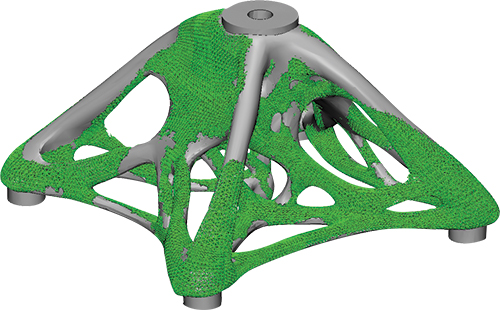

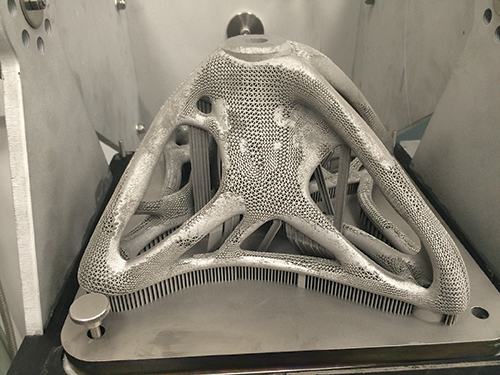

The spider bracket mimics the biological structures as one would find in nature (Fig. 1). Altair’s topology optimization software created a unique, organic shape that is both light and strong. The lattice structures also provide stability and are desirable for their thermal behavior. However, a topology-optimized model needs sufficient smoothing before it can be printed.

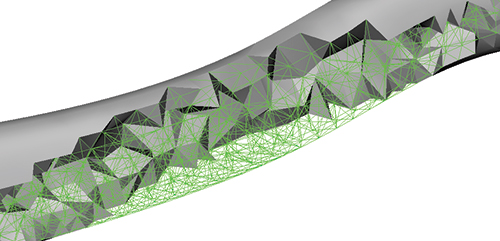

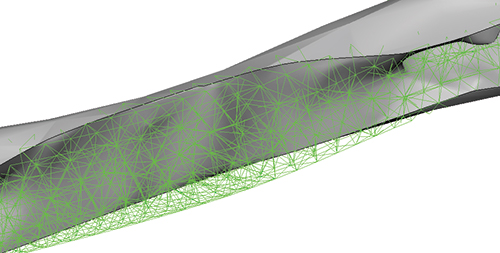

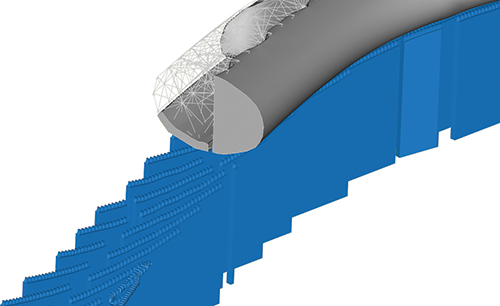

The topology optimization resulted in solid regions and regions with a lattice structure (Fig. 2). The irregular interface between the lattice and the solid mesh makes 3D printing difficult and can lead to stress accumulations, meaning that this interface requires reconstruction (Fig. 3). That’s where Materialise 3-matic software comes into play, according to Materialise officials. With this design-optimization software for AM, the design engineers at Materialise easily transformed the rough data into a clean model with smooth surfaces (Fig. 4).