Stuart Keeler

Stuart KeelerMaking College Graduates Job-Ready

September 1, 2016Comments

How many times have college seniors attended their graduations, received their diplomas and reported the following Monday to a full-time job in a sheetmetal-manufacturing plant? Are fresh graduates ready to start day one with a usable knowledge base and an understanding of the daily language? A graduate should not require several months on the job before being able to work without a translator and daily guide.

Most colleges and universities employ excellent professors and great teaching programs. Unfortunately, some lack a key segment or two of information. Here are some issues and remedies.

1) Press-shop jobs are not “cool”—students have misconceptions about career paths.

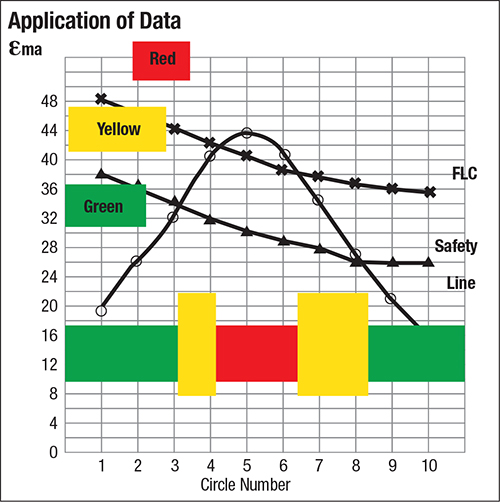

Decades ago, many press-shop jobs were not the best—lube a blank, insert it into the die, push the button to cycle the press, remove and stack the part. However, working in modern press shops presents more interesting opportunities, dealing with advanced high-strength steels, for example, and new lubricants, computerized controls and more. Better tools for process tracking are used, including ultrasonic thickness gauges, laser thermometers, computer-operated tensile-test machines, and virtual forming and data-driven analyses. Using virtual forming, for example (Fig. 1), can help predict if a new part will fail in the press before die construction begins. Technology has become very cool.

Fig. 1—The red zone in the center peak predicts stamped-part failures during production.

2) Proper classroom instruction is needed.

One can spend 4 yr. at a university gaining a tremendous amount of knowledge. But the learning is a complete waste of time if the knowledge is not consistent with actual job requirements. For example, which of the following topics is most important to prepare a student for a job in an automotive press shop?

A) Understand the 27 workhardening equations, their derivations and applications.

B) Understand the power law, forming-limit curve, n-value, maximum allowable strain gradient and forming quality issues.

C) Know all of the standards for running a hardness test.

For the job-ready candidate, the knowledge presented in answer B best describes the information needed to make successful parts in a press shop. A is the correct answer for researchers working in a lab. And, the ability to run hardness tests (C) to determine the resistance of a sheetmetal surface to wear is not useful for determining material stretchability.

To become even better prepared for graduation day, some students search for opportunities to undergo on-the-job training during their 4 yr. of classes. They can:

• Work at summer internships/jobs

• Look for weekend or second-shift jobs

• Attend schools with co-op programs

• Learn from a textbook (always the second choice; learning to solve problems in the field always is preferred).

Podcast

Podcast