Synchronization Aided Via Electrics

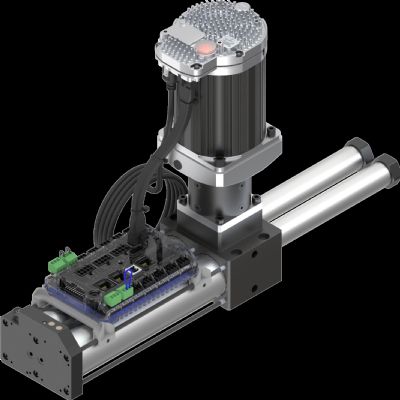

This brings about the development of electric actuators. Electric cylinders, slide packages and rotate modules are becoming more commonplace in transfer-die applications as their performance (torques, timing and operating voltages) and packaging improve. And, the price point of these devices has dropped to where they begin to make sense in transfer tooling. Electric actuators could quiet many of the concerns stampers have with actuator synchronization and reliability.

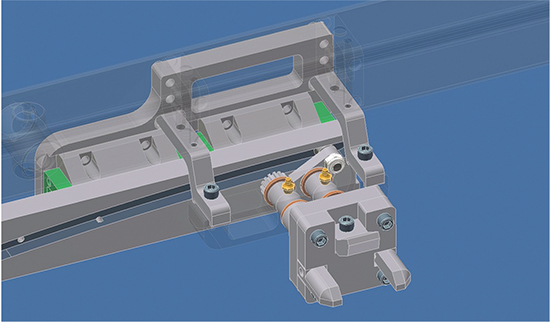

Small stepper motors with integrated controllers take the complexity out of homing, synchronization and feedback monitoring. These can be purchased with absolute feedback encoders, and typically are “point-and-shoot” types of controls, as opposed to electronic line-shafted functionality where a preprogrammed motion profile (or a series of profiles) and ramp rates are developed, and the device awaits an initiate signal. With a typical operating voltage of 12 to 48 VDC, stepper motors with integrated controls are well-suited for under-the-ram applications.

One of the challenges here is predicting where these devices may be required in a future green-field transfer-press application. When stampers account for this up front in the design cycle, applying this capability to the capital equipment to satisfy a tooling requirement can be fairly straightforward. Priorities during system design should include connectivity, cable management and correct power-up sequencing to ensure a hands-free quick-changeover sequence.

Application Survey

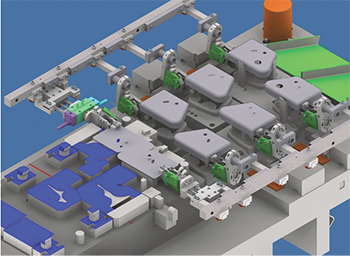

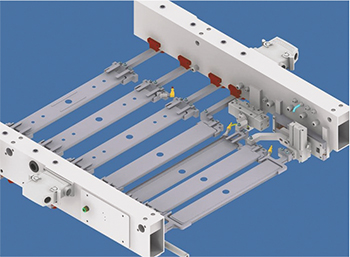

Let’s look briefly at two creative applications of transfer tooling that conserve material and open up die space.First, consider the two-out process illustrated in Fig. 1, where the material is cut from a coil strip and the stamped parts developed to optimize material usage and produce minimal scrap. Parts are nested in the coil and then run unattached. Both are moved away from the centerline of the press to create additional die space. One part is rotated 180 deg. to allow for even more die space and to further improve part handling.

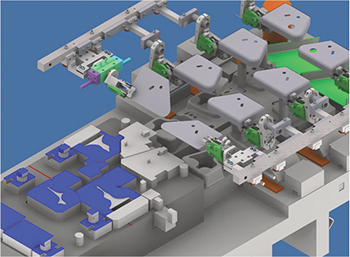

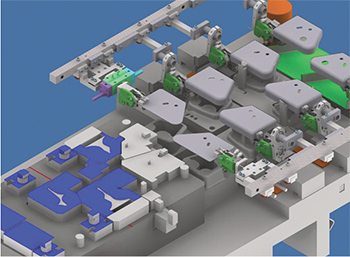

In the example shown in Fig. 2, two parts are stamped out in the direction of flow. The transfer runs at double pitch, and the parts are individually trimmed, formed, pierced and flanged. The parts then are stacked in the final operations to allow for the two stampings to be crimped into one finished component, which then is evacuated from the press.

Any process that requires two parts to be joined could be a candidate for this technique. It has been proven to eliminate secondary operations in several applications within the HVAC, appliance and automotive, among others. MFView Glossary of Metalforming Terms

See also: HMS Products Co.

Technologies: Pressroom Automation, Tooling