seen at fabtech

Smoother Linear Motion via Protected, Easier-to-Maintain Roller Bearings

October 25, 2024Comments

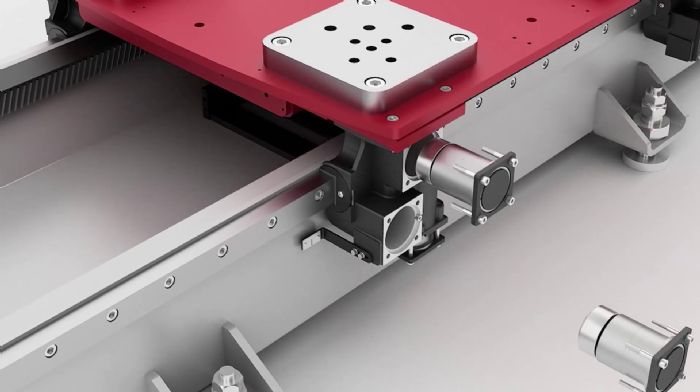

Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.

Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.

Güdel tracks feature a wiper/scraper combination on the block that scrapes the rail clean of debris including paint and weld spatter. The roller’s bearings are completely enclosed to keep out contamination while their larger size also enables the track to better roll over left-over debris.

While adding linear motion to articulated robots is a widely adopted solution to extend flexibility and work envelopes, these benefits only apply if the robot runs smoothly on a track that in many production environments will be exposed to dust, soot, abrasives and fine contaminants, explain company officials. These can cause the track’s roller bearings to stop rotating, leading to malfunction and robot downtime. And, when manufacturers need access to service roller bearings, they typically must remove the entire carriage, robot, or payload away from the track, often needing a crane.

Güdel’s fully contained cam followers keep contaminants out while being simple to maintain. When servicing Güdel’s cam followers, users only need to slide out the cartridge containing the bearings on the side of the rail. Removing, replacing and adjusting the cam follower only takes 10 min., company officials report, while standard profile guides likely require an entire production shift as a robot idles.

See also: Gudel, Inc.

Technologies: Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationRobot Versatility on Display at the Kuka Booth

Friday, June 27, 2025

Pressroom Automation

Pressroom AutomationAutomatica Trend Index: Robots Welcome in U.S. Manufacturing...

Friday, June 27, 2025