Robots Slide and Glide

November 1, 2009Comments

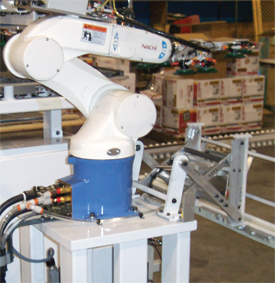

Three stamping-press-tending robots at metal-furniture manufacturer The HON Co. ride floor rails to move from press to press, serving up sheetmetal blanks to two-station transfer dies.

A vigorous rapid-continuous-improvement (RCI) program directed toward ongoing training and implementation of productivity-enhancing manufacturing projects has earned The HON Co. plant in Cedartown, GA, heaps of industry recognition. The list of awards|

One Powerful Lean Tool: 3P

|

RCI drives all of the innovative ideas that pour out of The HON Co.’s 600 employees, as they strive to improve safety and quality, reduce costs and improve productivity.

Stamping-Press Productivity ProjectThe HON steel-fabrication department supplies four assembly lines in the plant, two of which manufacture vertical filing cabinets, one which makes metal desks, and a fourth line that assembles lateral files and storage cases, shelf files and bookcases. Early in 2000, an RCI project had a HON work team focused on improving the safety and productivity of its stamping-press operations within the steel-fabrication department. There, presses hem 0.022-in.-thick mild-steel blanks for drawer fronts, in two sizes to accommodate letter- or legal-size files. Hand feeding of blanks into two-station transfer dies at a production rate of 400/hr. taxed the firm’s press operators, who used gripper wands to move the blanks rather than reach into the dies. The process proved safer than hand feeding to be sure, but manipulating blank after blank on the end of the wands led to ergonomics issues—carpal tunnel syndrome to be exact.

“An RCI project to improve the three press lines that hem filing-cabinet drawer-front blanks led us to investigate the use of robots to handle the blanks,” recalls HON maintenance engineer Burt Coffman. Noting his skepticism at the time, Coffman says, “I didn’t think there was any that this would work. But the robots we’ve put on those lines are unreal. Productivity is fantastic, and they don’t take breaks.”

A 3P (production preparation process) project proved out the robotic press-tending cell arrangement and HON brought in local robot integrator TEC Automation, Inc., Canton, GA, to manage the project. The first press robot went online late in 2000, a second in 2001, the third in 2003, and the plant will fire up its fourth press-tending robot before the end of 2009. Each robot tends two presses, one tooled for stamping legal-size drawer parts, the other for letter-size parts. Robots rides a track to access the two presses, with a hard stop and locking mechanism to secure the robot at the press. Presses are 100- and 150-ton models with 8-in. stroke to accommodate the robot end-of-arm tooling. Robots are ABB (one) and Nachi (three) six-axis pedestal-mounted units.