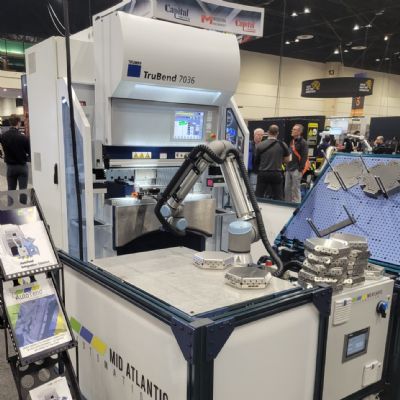

seen at fabtech

Integrating External Axes Enables More-Sophisticated UR-Cobot Applications

October 28, 2024Comments

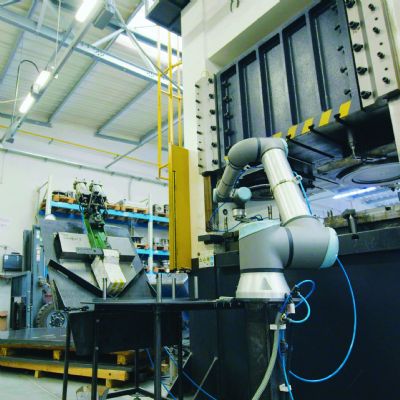

Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s collaborative robots (cobots). The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications demonstrated in the booth, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s own controller.

Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s collaborative robots (cobots). The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications demonstrated in the booth, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s own controller.

“Having the cobot sync with a rotary positioner or a linear rail, and timing it within milliseconds, means that users now can weld parts efficiently whereas before they normally couldn’t because they’d either have to stop and manually move the part, or weld it at two different times,” explains Will Healy III, global industry leader of welding at Universal Robots. “To our knowledge, this is the first time that multi-axis cobot welding with coordinated motion is showcased in North America.” MotionPlus enables these capabilities, allowing UR’s welding partners to add dual-axis coordinated motion capabilities to their own solutions. For example:

- Vectis Automation leveraged MotionPlus, launching the Revo dual-axis system at FABTECH. The new multi-axis positioning method can tackle more complex multi-faceted parts and excel in situations where the fabricator must orient parts relative to gravity. Vectis also showcased QuickTeach and AI Path Optimization. QuickTeach allows the cobot user to teach points and optimize paths right at the torch. AI Path Optimization applies user-defined work angles, push/pull angles and smoothed corner transitions to the weld path, thus ensuring that the weld always is created according to procedure specifications.

- THG Automation demonstrated multi-axis welding (see video) through THG Multi-motion, featuring a dual-axis skyhook with a part welded by a UR cobot mounted on a rail. THG also launched THG-Multi-Op: two all-in-one systems, one for gas-metal-arc/tungsten-metal-arc welding, and another for cutting and welding. Each system employs a tool changer that allows the operator to switch easily between applications. Other new THG products at FABTECH included a laser welding system and a new mobile base that provides user flexibility in orienting a cobot system with unusually sized and shaped parts.

See also: Universal Robots, Vectis Automation, THG Automation, LLC

Technologies: Pressroom Automation, Welding and Joining

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationRobot Versatility on Display at the Kuka Booth

Friday, June 27, 2025