seen at fabtech

Automation for Laser Cutting and Press Brake Bending

November 1, 2024Comments

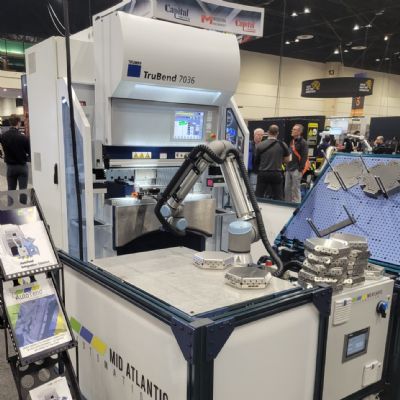

Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press-brake cell (seen in the video), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser-cutting machines.

Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press-brake cell (seen in the video), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser-cutting machines.

With the ByCell Bend Star M, metal formers gain the benefits of a fully loaded bending cell but with the advantage of a compact, modular layout. The cell features a footprint measuring 21.32 by 20.34 ft. and comes equipped with a Kuka Iontec robot and automatic tool-change system using RFID technology. A vision system eliminates any wasted time caused by referencing—typically 10 to 15 sec. per part, we learned from company officials.

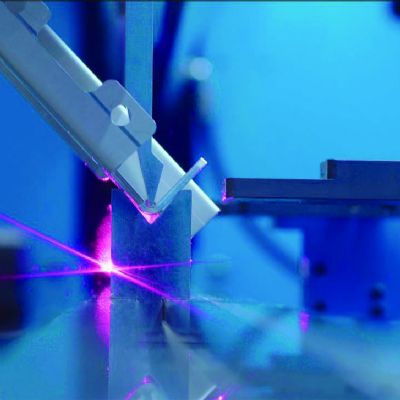

And for shops looking to automate their laser-cutting

process, Bystronic debuted the ByLoader Flex 3015. It employs material pallets beside

the shuttle table for efficient loading of raw material onto the shuttle table,

and then quick unloading of the cut sheet onto pallets. The setup can use a combination

of two to five pallet positions. And, aiming to conserve energy, suction cups

can be activated independently.

And for shops looking to automate their laser-cutting

process, Bystronic debuted the ByLoader Flex 3015. It employs material pallets beside

the shuttle table for efficient loading of raw material onto the shuttle table,

and then quick unloading of the cut sheet onto pallets. The setup can use a combination

of two to five pallet positions. And, aiming to conserve energy, suction cups

can be activated independently.

See also: Bystronic Inc.

Technologies: Bending, Cutting, Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Vineyard Machine Maker Harvests Productivity by Bringing Las...

Kate Bachman September 30, 2024