Two-Press Robotic Cell Supports Lights-Out Aluminum-Forming Operations

April 11, 2023Comments

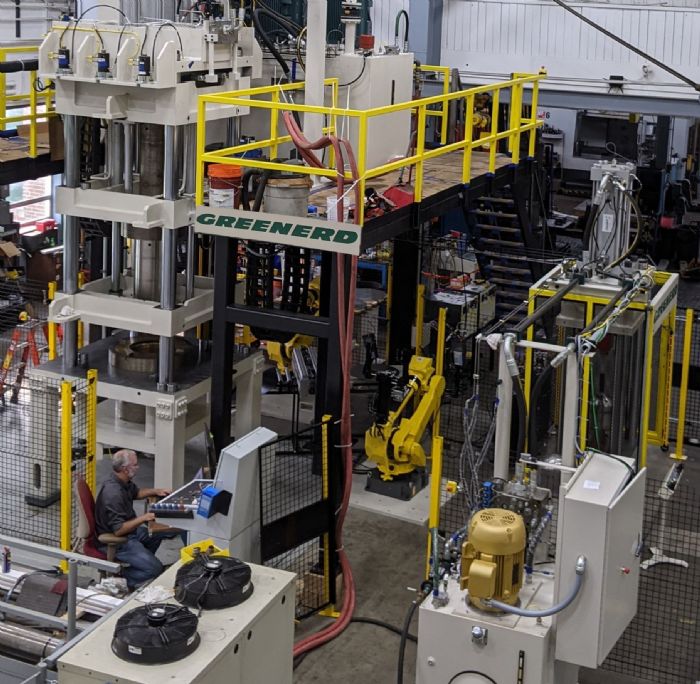

Greenerd Press & Machine Co., Nashua, NH, has developed an

automated two-press, two-robot production cell enabling unattended production

of large aluminum pressure vessels. The cell employs sensors to locate a pallet

of blanks. Then, a Fanuc robot picks an individual blank from the stack,

detects and rejects any double blanks, and transfers the blank to an automated lube

station. The robot then picks a previously lubricated blank and loads it into a

hydraulic deep-draw press. During production, a second robot catches and

transfers formed parts to a second hydraulic press for a punching operation. A

centralized control station sets the operating parameters of both presses and

controls the action sequences of the robots.

Greenerd Press & Machine Co., Nashua, NH, has developed an

automated two-press, two-robot production cell enabling unattended production

of large aluminum pressure vessels. The cell employs sensors to locate a pallet

of blanks. Then, a Fanuc robot picks an individual blank from the stack,

detects and rejects any double blanks, and transfers the blank to an automated lube

station. The robot then picks a previously lubricated blank and loads it into a

hydraulic deep-draw press. During production, a second robot catches and

transfers formed parts to a second hydraulic press for a punching operation. A

centralized control station sets the operating parameters of both presses and

controls the action sequences of the robots.

"Increasingly, our customers seek turnkey robotic and other product-handling solutions,” says Greenerd president and CEO Jerry Letendre. “Today's challenging applications require manufacturers to implement automated press solutions that are flexible, productive and reliable."

See also: Greenerd Press & Machine Co., FANUC America, Inc.

Technologies: Pressroom Automation, Stamping Presses

Video

Video