Scanning Spray Eases Machining of 3D-Printed Metal Parts

November 23, 2022Comments

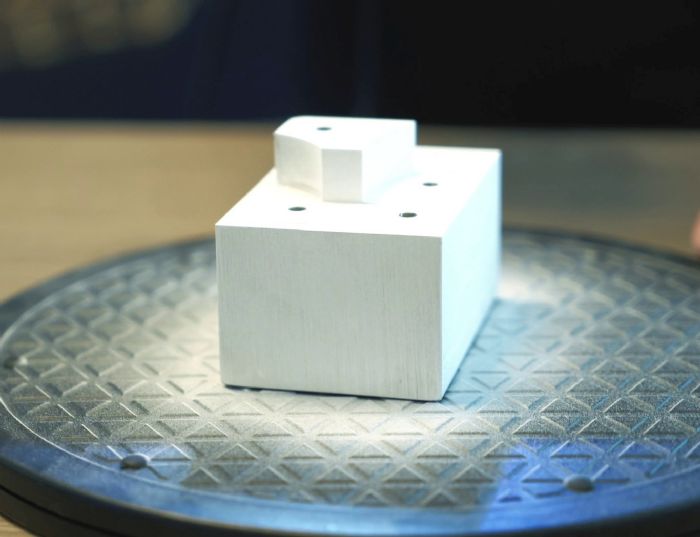

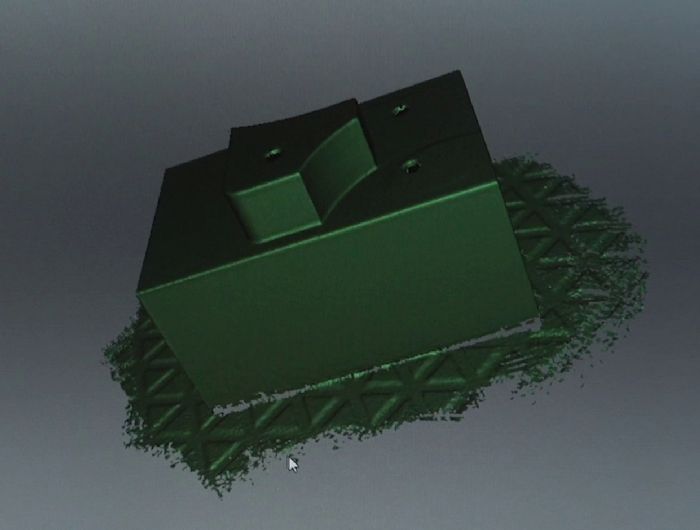

Precise milling processes require precise positioning of the workpieces on the machine table. The machine tool’s tactile measuring sensors determine the position and location of the parts to be milled, and the milling programs are set accordingly. However, the integrated measuring sensors have only limited suitability for 3D-printed metal parts, explain officials from Aesub, a provider of scanning sprays. They cannot fully detect the position of the freeform shapes in the 3D space. The large shape and geometry tolerances (+/-0.3 mm or more depending on the workpiece size) of 3D-printed parts require detailed optical measurements. These are either performed with a hand-held scanner directly in the machine tool, or on a removable zero point-mounting system plate outside of the machine. Using the data obtained, fine-tuning of the milling program to match the workpiece position takes place.

Precise milling processes require precise positioning of the workpieces on the machine table. The machine tool’s tactile measuring sensors determine the position and location of the parts to be milled, and the milling programs are set accordingly. However, the integrated measuring sensors have only limited suitability for 3D-printed metal parts, explain officials from Aesub, a provider of scanning sprays. They cannot fully detect the position of the freeform shapes in the 3D space. The large shape and geometry tolerances (+/-0.3 mm or more depending on the workpiece size) of 3D-printed parts require detailed optical measurements. These are either performed with a hand-held scanner directly in the machine tool, or on a removable zero point-mounting system plate outside of the machine. Using the data obtained, fine-tuning of the milling program to match the workpiece position takes place.

The problem: High material costs for 3D-printed parts keep machining

allowances small. The milling process must be extremely precise. Capturing the

freeform surfaces, however, is more complicated than with standard milled parts.

Added to this is the fact that some 3D-printed parts may be shiny, and in some

cases have deep recesses. These surfaces cannot be fully captured by many

scanners. Here is where scanning spray from Aesub can help.

The spray mattes shiny metal surfaces in a few seconds, allowing for immediate measurement. The scanner can fully capture the matted surfaces, leading to faster availability of reliable workpiece data. In particular with small production runs and prototype production/first-article inspection, scanning sprays help to speed measuring, and, thereby, the machining processes, and avoid waste.

The spray mattes shiny metal surfaces in a few seconds, allowing for immediate measurement. The scanner can fully capture the matted surfaces, leading to faster availability of reliable workpiece data. In particular with small production runs and prototype production/first-article inspection, scanning sprays help to speed measuring, and, thereby, the machining processes, and avoid waste.

Sublimating scanning sprays from Aesub, which can be sprayed directly onto workpieces in machines, reportedly completely vanish after a short time, removing the need for subsequent cleaning of the workpiece and machine. AESUB currently offers three sprays with different sublimation times.

Technologies: