ExOne, Maxxwell Motors Partner on Developing Copper Electric-Motor Windings

August 19, 2021Comments

ExOne has announced collaboration with Maxxwell Motors, a Tennessee startup, on development of a unique copper-winding design for Maxxwell’s axial flux electric motors. The motors would be destined for electric cars as well as heavy-duty vehicles and industrial devices.

ExOne has announced collaboration with Maxxwell Motors, a Tennessee startup, on development of a unique copper-winding design for Maxxwell’s axial flux electric motors. The motors would be destined for electric cars as well as heavy-duty vehicles and industrial devices.

Optimized copper windings and rotors in electric motors help enable the auto industry’s transition to hybrid and pure electric-power vehicles. But current methods of manufacturing the windings, according to ExOne and Maxxwell officials, prove costly, inefficient, and limit designs in a way that also limits their performance.

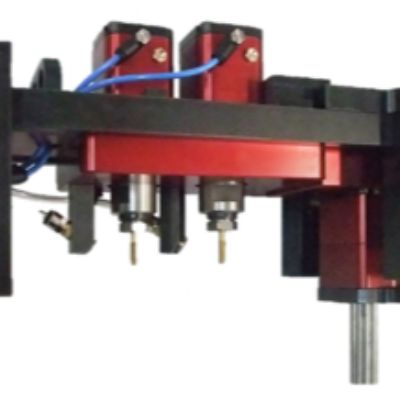

For example, one of Maxxwell Motor's patented electric-motor designs features copper coils for the stator winding that fully surround the motors to conduct electricity. A standard motor design employs 36 coils in two specific areas of the design, but Maxxwell and ExOne aim to consolidate all the coils into a single 3D-printed part, saving time and money. Binder jetting winding assemblies as a monolithic piece can eliminate the need for coil wrapping, bending, tooling and welding of individual parts together.

The partnership already has proved out a new concept for binder jet 3D printing a high-efficiency design in copper that reportedly eliminates many of the above-mentioned challenges. Additional development and testing now are underway.

See also: Desktop Metal

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingWaterjet Optimizes Accuracy, Minimizes Taper

Thursday, July 3, 2025

In-Die Operations

In-Die OperationsUnits for In-Die Tapping and Insertion

Wednesday, July 2, 2025