System Enables Efficient, Safe Handling of Metal-AM Powder

August 17, 2018Comments

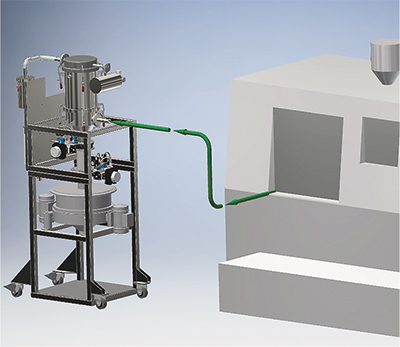

The newly introduced metal-powder recovery system by Vac-U-Max, maker of pneumatic systems and support equipment, increases productivity of additive-manufacturing (AM) machines by extracting powder from the printing bed using vacuum and then sieving the powder for future use. The closed-loop system prevents operators from coming into contact with the powder.

System features include:

- Compressed air-driven vacuum generator with ½-in. NPT high-pressure air connection and variable orifice assembly for adjustment of vacuum levels. The generator requires 35 cfm at 60 psi.

- Vacuum receiver package with 36 sq. ft. of filter area and counterweighted discharge valve. The component is made of 316L stainless steel.

- High-output suspended vibratory sieving machine with US230 stainless-steel mesh and ultrasonic deblinding kit.

- Control panel that incorporates a microprogrammable logic controller for vacuum-conveying functions, starter for sieve, ground and bonding monitor, and face-mount ultrasonic controls.

- Rolling-square-tubular frame with locking casters and made of powder-coated steel.

Vac-U-Max: www.vac-u-max.com

See also: Vac-U-Max Inc

Technologies: