Rutuja Samant

Rutuja SamantPowder Recyclability Factors Into Future of Metal Additive Manufacturing

February 20, 2019Comments

Fact: The cost of metal additive manufacturing (AM) continues to increase, as manufacturers push conventional metal-powder producers to provide specialty powders designed for applications in the aerospace, defense and biomedical sectors. This reality places growing importance on powder-recycling efforts.

Understand Powder Degradation

|

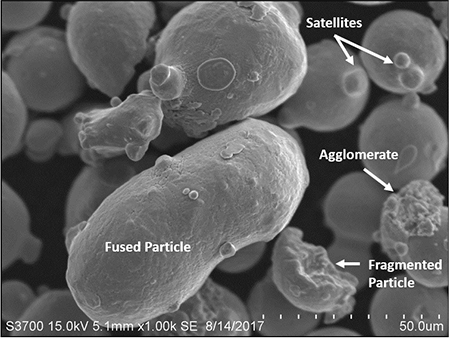

| Fig. 1—Powder degradation after multiple laser powder bed fusion builds. |

High-temperature powder alloys such as Inconel 718, generally chemically stable over many powder recycles, are limited by physical traits such as morphology and flowability when evaluating reusability. As these materials melt at higher temperatures, the material surrounding the melt becomes distorted and sintered together, which can make powder particles larger and unusable.

On the other hand, titanium powders are more susceptible to oxygen pickup, and, therefore, can be used only a couple of times before the powder falls out of specification due to high oxygen content.

Thus, understanding the degradation behavior of different types of powders is important for developing standards for powder recyclability that don’t exist today.

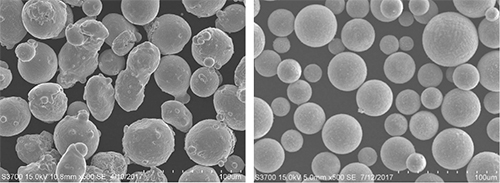

In a recyclability study performed with a high-temperature material at EWI, researchers used and analyzed powder through multiple, laser-powder-bed-fusion (L-PBF) builds to understand the effects on powder and part properties. Fig. 1 shows a scanning-electron-microscope image of degraded powder after multiple AM runs. Through the course of these builds, satellites attached to larger powder particles started separating out, creating smaller individual particles. Meanwhile, powder particles started fusing together to form agglomerates with particles fragmented into incomplete particles. All of this affected the flow and packing density of the bulk powder, with particle-size distribution widening and the powder’s oxygen content increasing. However, after 13 consecutive builds with the same batch of powder, the powder still fell within the composition specifications, making it a viable candidate for reuse.

Podcast

Podcast