Work Hardening is Your Friend

June 10, 2021Comments

Forming forces exceeding a material’s yield strength create the plastic deformation necessary to produce an engineered stamping. As deformation continues throughout the press stroke, metal alloys strengthen from a process known as strain hardening (or work hardening), which reduces the tendency for localized thinning in highly deformed areas. This leads to the characteristic parabolic shape of a stress-strain curve between the yield and tensile strengths.

Work hardening is characterized by the n-value—related to the slope of stress-strain curve. More formable material grades have higher n-values, meaning that for the same amount of strain created by the part design, more formable grades strengthen to a greater extent.

Exploiting this phenomenon, it may be possible to create a lighter-weight high-strength steel from mild steel. While this may sound too good to be true, achieving this may require a change in forming methods from draw forming to stretch forming.

Estimating the yield strength of a formed panel requires knowledge of the forming strain and the as-received (flat sheet metal) mechanical properties determined from tensile testing. Several techniques measure forming strain, such as manual circle-grid strain analysis, camera-based noncontact analysis methods or even commercial simulation programs. These techniques may show individual strains in each direction.

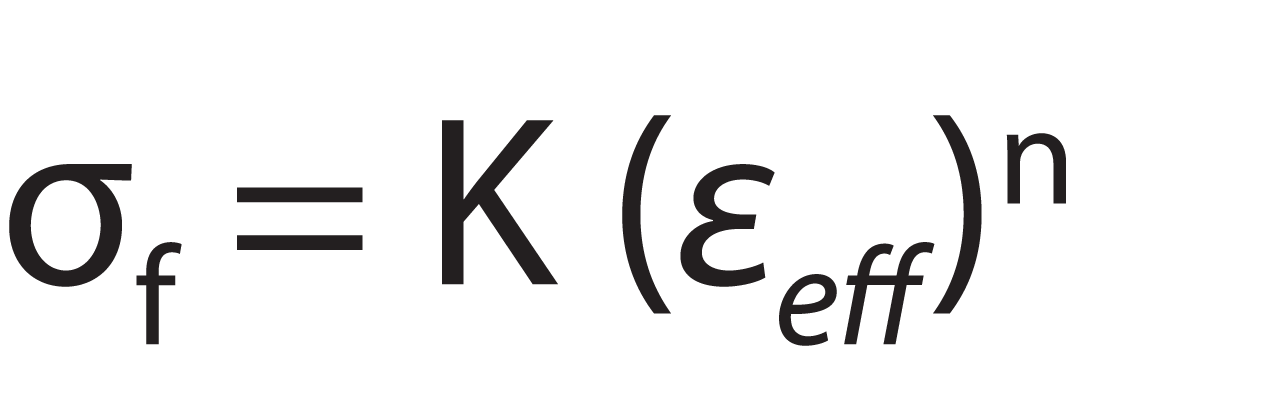

The formed panel yield strength (σf) can be estimated as:

where we determine n (work hardening exponent) and K (strength coefficient) from the true stress-true strain data at strains up to εu, the strain at uniform elongation. εeff is the effective strain, a way to combine the biaxial effects of ε1 (major strain) and ε2 (minor strain) into a single term.

Note: The equations shown here are for steel grades. Estimating the strength of aluminum alloys requires different equations, but the same general concept applies.

For more than 50 years, researchers have been defining terms and methodologies to best describe effective strain. The simplest way is to just define effective strain as the sum of the major and minor strains:

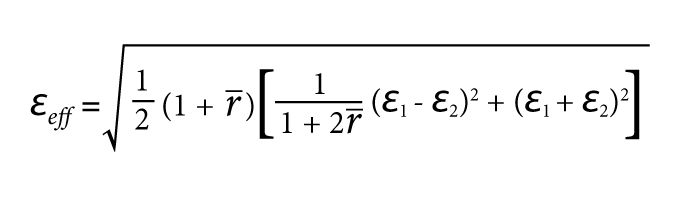

Hill developed a more complex relationship, in 1948, using r̅ (or r-bar), the plastic anisotropy ratio. There have been refinements over the years, and this equation suffices here:

Hill developed a more complex relationship, in 1948, using r̅ (or r-bar), the plastic anisotropy ratio. There have been refinements over the years, and this equation suffices here:

This equation provides the tools needed to choose between designing the forming process for higher-strength steel (likely also requiring a higher purchase price) or obtaining the needed strength by forming a panel made from lower-strength steel.

This equation provides the tools needed to choose between designing the forming process for higher-strength steel (likely also requiring a higher purchase price) or obtaining the needed strength by forming a panel made from lower-strength steel.

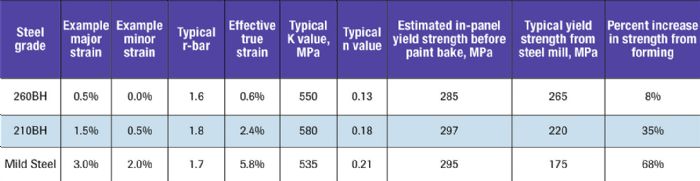

Take this a step further: Transitioning from draw beads to lock beads holds the panel even tighter, possibly allowing the use of mild steel while still achieving the same strength in the formed part. In the example highlighted in the table, stretching mild steel by just a few percentage points results in more than a 60-percent increase in yield strength as compared to the strength of the incoming flat sheet.

Take this a step further: Transitioning from draw beads to lock beads holds the panel even tighter, possibly allowing the use of mild steel while still achieving the same strength in the formed part. In the example highlighted in the table, stretching mild steel by just a few percentage points results in more than a 60-percent increase in yield strength as compared to the strength of the incoming flat sheet.