Press Selection for Deep Drawing Higher Strength Materials

May 1, 2014Comments

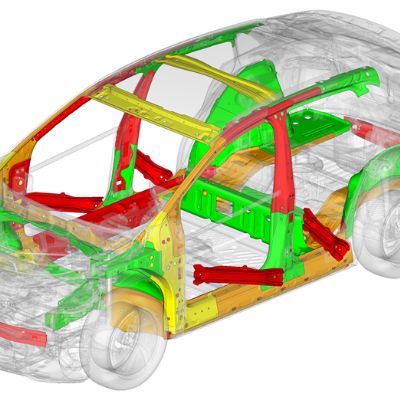

The application of advanced high-strength steel (AHSS) with ultimate tensile strengths of approximately 800 MPa are well established within the automotive industry. Trends indicate growth in applications requiring even higher-strength grades up to 1400 MPa and beyond.

Stamping materials at these strength levels affects the size, strength, power and overall configuration of every major piece of the press line, including coil-handling equipment, material-feed systems, straighteners and stamping presses. Deep drawing higher-strength materials requires special attention to press selection, particularly press tonnage and energy.

Press Tonnage

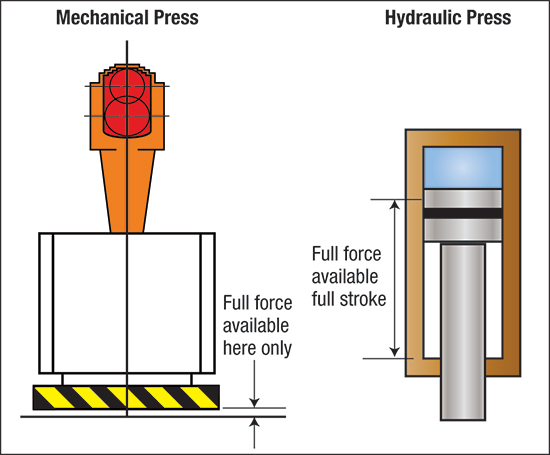

The tonnage rating of a press is the maximum load that can be exerted in continuous operation without causing damage to the machine structure or its drive system. The tonnage rating of direct-drive mechanical presses usually is determined at a slide position between 1⁄32 and ¼ in. above bottom dead center (BDC), depending on machine design and the manufacturer.

The available working force (tonnage) in mechanical presses decreases as the working distance above BDC increases. This tonnage de-rating occurs because the lever arm angle—the relationship between the crankshaft angle and the pitman—has reduced mechanical advantage higher up in the stroke. This is true for flywheel- and servo-drive mechanical presses. Tonnage de-rating curves—specific to a given press design and construction—are particularly important to understand and apply to deep-drawing operations where the drawing process can begin several inches above BDC.

Fig. 1

Hydraulic presses, which do not rely on mechanical linkages to transmit force to the workpiece, often get the call for difficult deep-drawing operations. The full force of the press machine rating is available anywhere within the operating stroke of the press (Fig. 1). Their operating speeds are limited due to the time required to remove latent heat from the hydraulic system.

Press Energy

The energy rating of a press is a function of the press load and the distance through which the load must be applied. The energy expended with each stroke must be replaced prior to the next stroke. In combination, the flywheel stores and delivers the required work energy while the electrical motor restores depleted energy by maintaining flywheel speed and avoiding excessive slowdown.

Forming and drawing processes can consume large amounts of press energy due to their long working distances. For example, pushing 50 tons through 1 in. of forming to stamp HSLA350 would require 50 in.-tons of energy, while deep drawing 3 in. requires 150 in.-tons of energy. Forming an AHSS grade material that is two times stronger— DP980 for example—would require 100 tons of force working through the same 3-in. distance. This requires a machine with at least 300 in.-tons of energy.

|

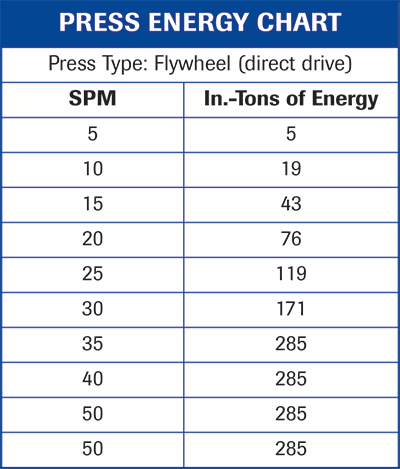

| Fig. 2 |

Stamping higher-strength steels requires higher blankholding and punch forces that result in substantial increases in frictional forces and interface temperatures. When interface temperatures reach a critical point, lubrication may break down and other forming and die-related problems can occur, such as thermal notching and galling. This can cause a stamper to reduce press speed to lower the process operating temperatures and avoid thermal-related forming problems.

Fig. 2 presents summary data extracted from an energy chart for a 600-ton press (the actual press-manufacturer’s table provides data in 1-stroke/min. increments from 0 to 60). The table clearly depicts the important relationship between press speed and energy. Full energy for this machine is available above 35 strokes/min. Below this speed, available energy rapidly diminishes. Slowing the press may reduce thermal problems associated with the higher-strength material, but there may not be enough kinetic energy remaining in the flywheel to carry out a continuous stamping process.

Servo-Drive Technology

One to address the “energy crisis” associated with deep drawing higher-strength materials is to consider the benefits of a servo-driven mechanical press. In a servo-drive press, high-capacity servomotors replace the flywheel, motor and clutch/brake. A servomotor can provide full energy and constant torque even at 1 stroke/min.

Other advantages of servo-drive presses include the ability to program stroke and slide velocity, to dwell anywhere in the stroke and to dwell at BDC—all without energy loss. These machines can offer high productivity, low maintenance and low energy costs.

Slide approach, forming speed and slide return speeds can be optimized to match the requirements of the forming process. This allows stampers to help reduce total cycle time and improve part quality.

Servo-drive presses also have been programmed to make multiple hits on a stamping at or near BDC, to help reduce springback. This may prove beneficial when forming AHSS materials due to their high propensity to spring back after forming.

When comparing flywheel- and servo-drive press technologies, remember that the fundamental principles of tonnage de-rating apply to both, even though there are key differences between the press types. Flywheel-drive presses also have limited energy that declines rapidly with slower operating speeds. Conversely, servo-drive presses provide full energy and constant torque at speeds as low as 1 stroke/min. MFView Glossary of Metalforming Terms

Technologies: Materials, Stamping Presses, Tooling