Mazda Develops Cold-Stamping Process for 1310-MPa HSS

April 22, 2019Comments

Mazda Motor Corp., via separate R&D projects with Nippon Steel & Sumitomo Metal Corp. and JFE Steel Corp., reports that it has developed the world's first cold-stamped vehicle body parts made from 1310-MPa high-strength steel (HSS). The parts, used in Mazda's new-generation Skyactiv-Vehicle architecture, are slated for upcoming models, including the Mazda3.

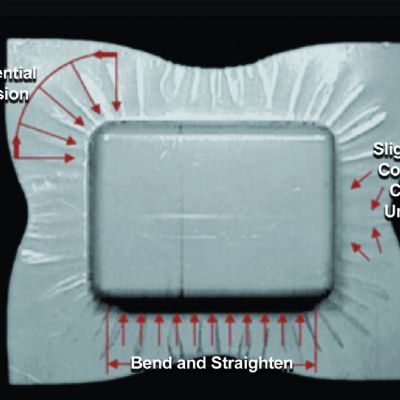

Until now, explain company officials, cold stamping of vehicle-body structural members has only been possible with 1180-MPa or lower-classed steel, due to the material's formability and the difficulty of ensuring dimensional accuracy after processing. But the company and its partners have developed process conditions that enable cold stamping of 1310-MPa HSS.

Technologies: Materials