In Sync: Steelmakers and Automakers

May 1, 2015Comments

For just over 100 years, the steel and automobile industries have been joined at the hip. For it was in 1908 when Henry Ford introduced the modern marvel, the groundbreaking Model T.

Question: What technology development, more than any other at the time, allowed Henry Ford to leapfrog from its 1903-vintage Model A to the wildly successful 1908 Model T?

Answer: United Steel Company’s production of vanadium steel at its plant in Canton, OH. The new steel was nearly three times stronger than previously used grades, considerably tougher and extremely machinable. In Henry Ford’s own words, according to the book “My Forty Years with Ford:”

“This means entirely new design requirements, and we can get a better, lighter, and cheaper car as a result of it.”

And so today, even with alternative materials knocking at the door, the steel industry continues to deliver the goods that allow automakers to develop better-performing, more fuel-efficient, lighter-weight and, shall we say, more affordable cars. While last month we aimed the spotlight on Ford’s aluminum F150 program, with this issue we recognize the continuing and strengthening relationship between steel and cars.

It’s said that Henry Ford changed the world, and if that’s true then certainly the collaboration between steelmakers and automakers continues to change the world. Each and every time the marketplace expects, if not demands, improved performance from its vehicles, steel steps to the plate. New models boasting remarkable characteristics send people to dealerships in droves and spark production and sales across numerous markets—not to mention the millions of jobs sustained and created.

Yes, the automotive and steel industries are interrelated pillars for growth, supporting an expanding global economy. And the ingenuity, innovative spirit and commitment of researchers, scientists and engineers working within both industries pull it all together.

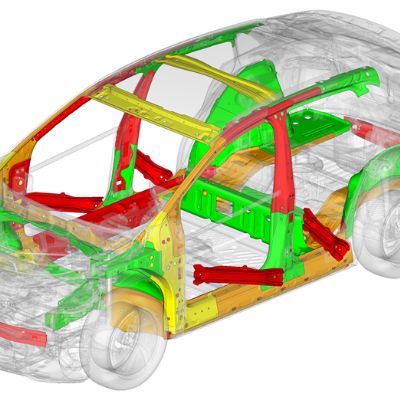

Our cover article in this issue of MetalForming illustrates just how in sync the steel and auto industries are. Presented are just a handful of the numerous new-car models that owe much of their glory to new steels: the 2015 Acura TLX, which uses six different grades of high-strength and advanced high-strength steels; the Chevy Colorado truck—71 percent of its body structure is of high-strength steels; and the Ford Edge, which boasts a 26-percent increase in stiffness over previous models, thanks to increased use of “new” steels.

Also noted—and not to be overlooked—are the accompanying metalforming-technology breakthroughs that open the doors to applying these new steels. These new materials allow designers to think out of the box, creating, for example, new opportunities for hot stamping to grow in use. We also see more rollformed parts than ever before in new platforms, and expanded use of tailor-welded sections.

And, let’s not forget the notable improvements in metalforming equipment designed to handle stronger steels—servo presses, new tooling materials and lubricants, and tough-as-nails coil-processing equipment come to mind.Technologies: Materials