Forming Aluminum Stampings—Part 1

March 1, 2009Comments

The benefits of aluminum for weight reduction and fuel savings in automotive applications have been well recognized for decades. The use of aluminum can reduce weight by 40 to 60 percent as compared to steel. The combination of low density, high strength and excellent corrosion resistance makes aluminum alloys attractive to the automotive industry and for thousands of applications outside the automotive industry. Recently, weight reduction and fuel economy have become greater foci among automakers, consumers and government regulators. As worldwide auto sales continue to lag, automotive-stamping suppliers are attempting to diversify by pursuing new customers in non-automotive markets. As a result, many contract manufacturers and tool and die shops accustomed to working primarily with steel stampings may find themselves confronted with aluminum products and their processes. Hopefully, the information presented here will prove helpful to anyone forming aluminum for the first time.

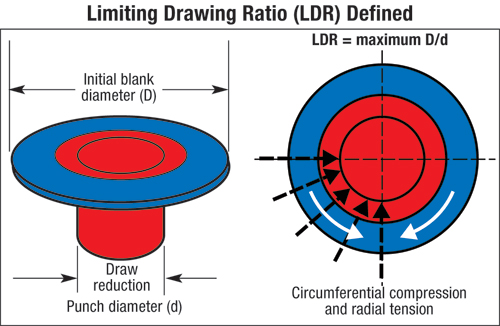

As a general comparison, it can be estimated that the formability of medium-strength aluminum is about two-thirds that of drawing-quality steel (Source: Aluminum Association, Publication AT3). The mechanical properties of aluminum differ significantly from that of steel and, therefore, it deforms differently during the stamping process. Clearly, aluminum stampings, their dies and manufacturing processes must be designed for the properties and characteristics of the aluminum alloy chosen for the stamping. Of primary concern are the material properties of the sheet, the geometry of the product, the geometry of the tooling and the press setup.

Material Properties

Aluminum has roughly 60 percent of the stretching ability of steel. Many automotive grades will form much like steel with 100,000-psi yield strength. Aluminum also has a thin natural layer of aluminum oxide on the surface. This hard oxide layer can be broken during the forming process and rapidly wear the forming tools. Consequently, tool-steel selection, heattreatment and surface treatments become very important. Furthermore, a light overall lubrication is required on both sides of the blank, even during blanking and shearing.

Aluminum also has one-third the Young’s modulus of steel. This reduction in Young’s modulus increases the likelihood for wrinkling, oil canning and other surface distortions. Although compensation for springback can be made in the stamping tools, the window between acceptable shape control and fracture is much less than that for steel. A successful aluminum-stamping die process combines good product design with good die designs.

Aluminum has a negative m-value, therefore, it has poor strain-distribution characteristics as compared to other materials with positive m-values, like steel. The ideal aluminum stamping design stretches evenly and distributes strains uniformly when deformed. The friction, die geometry, material properties and the forces restraining material flow into the die cavity combine to determine how the strain is distributed in a given stamping.