A More-Readily Machined 17-4 Stainless Steel

June 1, 2014Comments

Finnish company Outokumpu, with operations throughout the United States, has introduced Outokumpu 17-4 Prodec, promising improved machining characteristics. The new stainless-steel product, part of a family of Prodec grades, is produced at the firm’s Richburg, SC bar mill. It was developed as a direct result of growing market demand for better-machining 17-4 stainless steel, say company officials.

“Customers specify 17-4 because of its ability to be age-hardened, as well as for its high strength and corrosion resistance,” says Lou Kern, senior vice president for Outokumpu Stainless Bar. “But many of our customers were looking for the premium machining performance in 17-4 that they have come to expect in our specialty grades.” The result: 17-4 Prodec in bar form.

Testing has shown that the new material, when compared to standard 17-4 stainless steel, not only offers improved machining characteristics but also delivers optimum chip formation and reduced tool wear. Outokumpu 17-4 Prodec is available in 9⁄16- to 6.5-in. dia.

Outokumpu: www.outokumpu.com

See also: Outokumpu Stainless

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

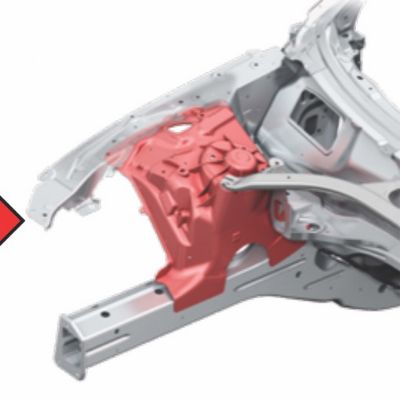

MaterialsGiga Stamping to Compete with Giga Casting

Eren Billur Tuesday, June 10, 2025

Materials

MaterialsNovelis Tests Industrial-Scale Use of Hydrogen in Aluminum-R...

Friday, February 28, 2025

Materials

MaterialsMetal Supermarkets in Ottawa, Canada, Under New Ownership

Friday, November 15, 2024