Factory-Reporting Software Updated to More Accurately Track OEE

September 1, 2009Comments

Honeywell Wintriss, Acton, MA, introduces Version 3.4 of its Line Efficiency Tracking Software (LETS) factory-reporting software, which allows metalformers to more accurately track overall equipment effectiveness (OEE) in applications where production rate is dictated by machine configuration. LETS automates the process of collecting production data from production machinery and processes.

Version 3.4 calculates OEE by applying an ideal rate for each part/machine combination. In previous versions, maximum machine speed represented the ideal rate for all jobs run on a machine. Now, the software improves the accuracy of OEE metrics in piece-part processes where the part design limits the speed of the job.

The software also adjusts the ideal rate by applying a factor based on the machine configuration. For example, in applications where each machine cycle produces more than one part, LETS Version 3.4 automatically multiplies maximum machine speed by that number of parts. And, in processes that require multiple machine cycles per part, it divides machine speed by the number of cycles.

“Through job changes, varying production rates and changing lot sizes, LETS Version 3.4 makes what should be an extremely difficult tracking process simple,” says Mark Hatch, product line director, Honeywell Wintriss. “As a result, discrete manufacturers can get an accurate account of their overall efficiency.”

Version 3.4 can precisely weigh the OEE percentages for jobs of varying lot sizes by keeping a running total of the actual parts produced by the machine over the series of jobs, and the number of parts that could have been produced according to ideal rates and multipliers. This enables the software to accurately summarize performance over time regardless of the number or length of the jobs running in the machine.

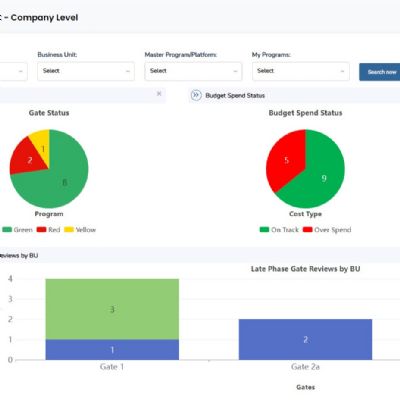

Also new with Version 3.4: a real-time performance dashboard that graphically compares the performance of current jobs and processes with user-selectable benchmarks. The dashboard allows users to quickly identify any processes that require immediate corrective action.

Honeywell Wintriss: 978/264-9550, www.wintriss.com

See also: Wintriss Controls Group LLC, ShopFloorConnect by Wintriss

Technologies: Management