The machine also includes automated features to ensure high-speed continuous operation, according to Amada officials. These features include autonomous monitoring of nozzle condition, pierce penetration, tip-ups and debris on the protective glass. Also included: Amada technologies such as Eco-Cut to provide quick piercing and rapid cutting with lower gas usage, and Smart Edge for providing good quality on sharp edges without modifying edge-cutting parameters.

Regius-series machines also feature Amada’s Ensis technology that automatically adjusts the laser beam’s properties to process a range of material thicknesses without additional machine setup. This high-speed fiber laser cutting system has the ability to cut thin materials as much as four times faster than a CO2 laser.

And, the innovative AMNC 4ie control is equipped with a large touchscreen that allows users to see information easily and load programs based on file name. Thumbnail views of parts or nests provide for rapid and simple identification to ensure that program editing on the shop floor is fast and efficient.

Cobot Tends Press Brake and Operates Touchscreen

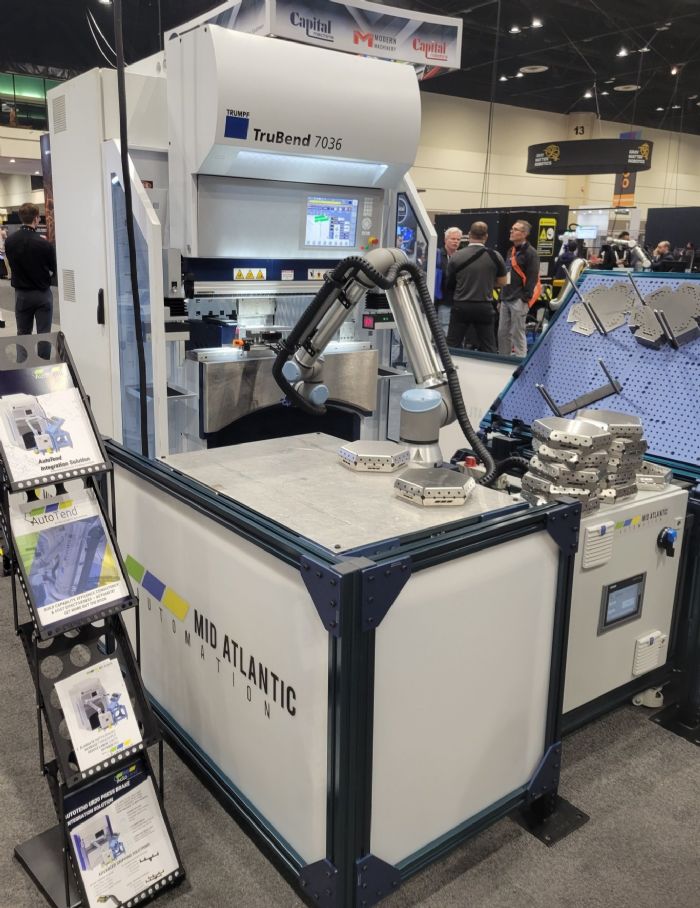

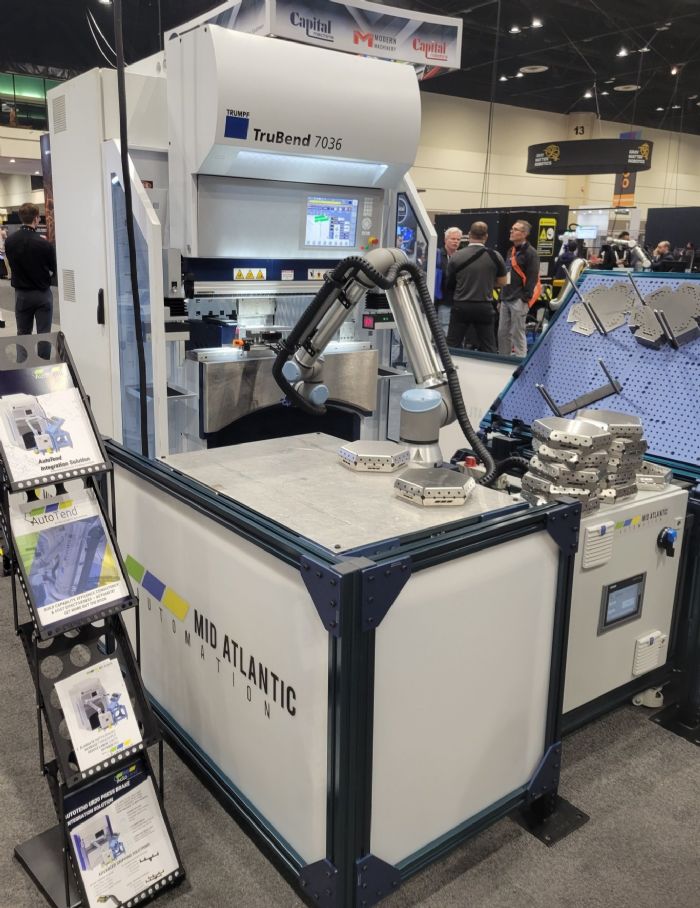

Integrator Mid Atlantic Machinery Inc. showcased its AutoTend robotic machine-tending setup, which employs a Universal Robots UR10e cobot to tend a press brake. At FABTECH, the cobot was teamed with a Trumpf TruBend 7036 press brake to form, via complex bends, type 304 stainless steel into a candy dish.

Integrator Mid Atlantic Machinery Inc. showcased its AutoTend robotic machine-tending setup, which employs a Universal Robots UR10e cobot to tend a press brake. At FABTECH, the cobot was teamed with a Trumpf TruBend 7036 press brake to form, via complex bends, type 304 stainless steel into a candy dish.

The cobot feeds material, orients it correctly and holds it while the press brake performs bends. Auto Tend integrates patented end-of-arm tooling that interacts directly with the press brake touchscreen control—an ideal solution for integrating cobot tending to an existing press brake, according to Mid Atlantic Machinery officials.

A recent visit by MetalForming to Argon Industries, Milwaukee, WI, provided an opportunity to see AutoTend in action on the shop floor. For more on Argon’s automation efforts, see the article in this issue.

Smoother Linear Motion via Protected, Simple-to-Maintain Roller Bearings

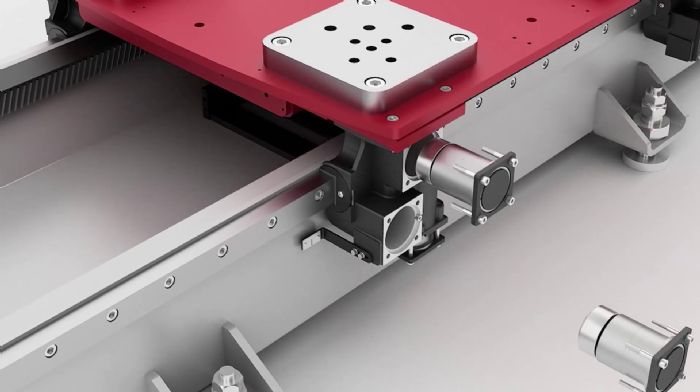

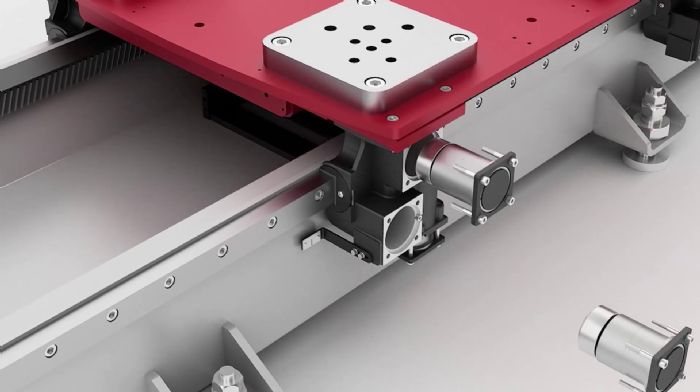

Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.

Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.

Güdel tracks feature a wiper/scraper combination on the block that scrapes the rail clean of debris including paint and weld spatter. The roller’s bearings are completely enclosed to keep out contamination while their larger size enables the track to better roll over left-over debris.

Güdel’s fully contained cam followers keep contaminants out while being simple to maintain. When servicing Güdel’s cam followers, users only need to slide out the cartridge containing the bearings on the side of the rail. Removing, replacing and adjusting the cam follower takes only 10 min., company officials report, while standard profile guides likely require an entire production shift as a robot idles.

New Machine Bevels While Laser Cutting, Reducing Downstream Processing

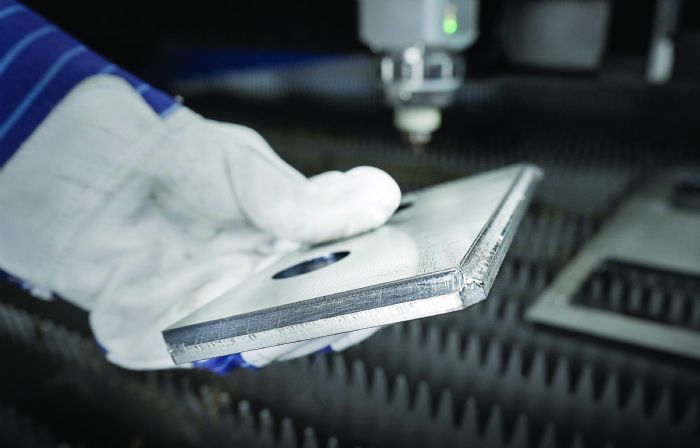

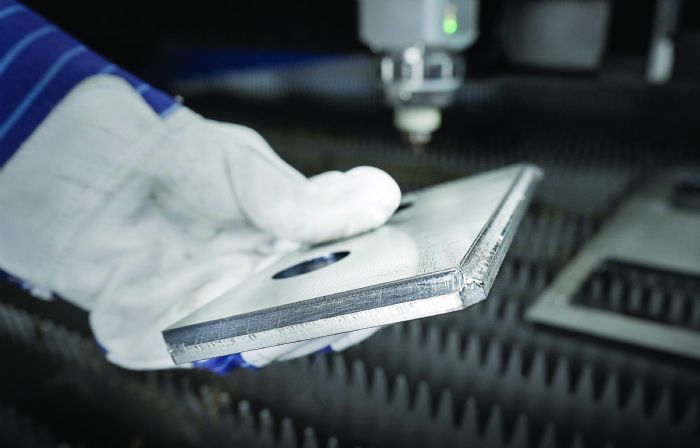

Trumpf unveiled its flat-sheet laser cutting machine, the TruLaser Series 3000 Bevel Cut Edition, which automatically prepares part edges for welding. It can produce beveled cutting edges, or chamfers, on the top and bottom of components while cutting, ensuring optimum preparation of welding edges and reducing downstream processes. Particularly suited for mild and stainless steel, the machine applies chamfers to sheets in thicknesses to 1 in., and reportedly handles complex bevel geometries with ease.

Trumpf unveiled its flat-sheet laser cutting machine, the TruLaser Series 3000 Bevel Cut Edition, which automatically prepares part edges for welding. It can produce beveled cutting edges, or chamfers, on the top and bottom of components while cutting, ensuring optimum preparation of welding edges and reducing downstream processes. Particularly suited for mild and stainless steel, the machine applies chamfers to sheets in thicknesses to 1 in., and reportedly handles complex bevel geometries with ease.

“Manufacturers now have a particularly productive universal machine with which they can integrate downstream process steps into laser machining,” says Grant Fergusson, Trumpf TruLaser 2D laser cutting product manager. “Thanks to the unique design of the cutting unit, the machine can create chamfers to 50 deg., depending on sheet thickness, which is more than the 45-deg. previous angle standard in the industry.”

The machine features two additional rotary axes, ultra-compact drive motors and a nozzle specifically developed for bevel cutting. Courtesy of a unique design, the cutting head can be tilted in all directions to an angle of 50 deg. And, the cutting unit regulates the distance to the sheet, minimizing the risk of collision despite the steep angle. The machine also comes equipped with Trumpf collision protection to further guarantee process reliability and prevent structural damage by avoiding collisions with tipped parts.

Direct-Drive Servo Press

Macrodyne Press Technologies introduced the press OEM’s TRU direct-drive servo press. Designed with industrial-screw technology driven by torque and servo motors, the press allows the slide to move up and down the same way that a hydraulic cylinder would, but under servo control and with no oil.

One advantage of the technology: The slide can oscillate as many as 30 times/sec. during the forming process. This allows stampers to form deeper draws—beyond what a hydraulic or servomechanical press currently can, say company officials.

The press provides ram force to 5000 tons; stroke and daylight to 12 ft. Maximum bed size: 20 by 12 ft.

Automation for Laser Cutting and Press Brake Bending

Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press brake cell (pictured), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser cutting machines.

Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press brake cell (pictured), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser cutting machines.

With the ByCell Bend Star M, metal formers gain the benefits of a fully loaded bending cell but with the advantage of a compact, modular layout. The cell features a footprint measuring 21.32 by 20.34 ft. and comes equipped with a Kuka Iontec robot and automatic tool-change system using RFID technology. A vision system eliminates any wasted time caused by referencing—typically 10 to 15 sec. per part, we learned from company officials.

And for shops looking to automate their laser cutting process, Bystronic debuted the ByLoader Flex 3015. It employs material pallets beside the shuttle table for efficient loading of raw material onto the shuttle table, and then quick unloading of the cut sheet onto pallets. The setup can use a combination of two to five pallet positions. And, aiming to conserve energy, suction cups can be activated independently.

Smart Cobot Welder with Seven-Axis Arm

Spartan Robotics introduced a smart cobot welder featuring a unique Kassow Robots seven-axis arm. The seventh axis facilitates better welding because it provides enhanced flexibility and precision, according to Spartan Robotics officials. The extra axis allows welders to navigate around challenging weld locations and tight spaces and to perform complex weld patterns. The setup also features an integrated free-drive button that enables programming of all cobot positions at one time. Users can choose pre-engineered or custom machine designs.

Spartan Robotics introduced a smart cobot welder featuring a unique Kassow Robots seven-axis arm. The seventh axis facilitates better welding because it provides enhanced flexibility and precision, according to Spartan Robotics officials. The extra axis allows welders to navigate around challenging weld locations and tight spaces and to perform complex weld patterns. The setup also features an integrated free-drive button that enables programming of all cobot positions at one time. Users can choose pre-engineered or custom machine designs.

Intelligent Robotic Systems Leverage Machine Learning, AI

Opening the door for the next stage of robotic automation and leveraging machine learning and artificial intelligence (AI) for more intelligent robotic systems, Yaskawa Motoman launched the Motoman Next platform. Company officials report that the platform is the first in the industrial-robot sector to have autonomous adaptivity and an open development environment that facilitates increased communication and expandable functionality, equipping robots with the ability to execute challenging tasks autonomously in unstructured environments.

Opening the door for the next stage of robotic automation and leveraging machine learning and artificial intelligence (AI) for more intelligent robotic systems, Yaskawa Motoman launched the Motoman Next platform. Company officials report that the platform is the first in the industrial-robot sector to have autonomous adaptivity and an open development environment that facilitates increased communication and expandable functionality, equipping robots with the ability to execute challenging tasks autonomously in unstructured environments.

“This new hardware architecture provides autonomous adaptivity to an environment, expanding robotic deployment into previously unautomated areas,” says product manager Chris Caldwell. “The ability to leverage cutting-edge technology with AI processing allows for more intuitive robot utilization with human-like perception, enabling information and work to be structured as conscious flow for extremely productive operations.”

Also displayed and demonstrated for MetalForming (see photo): the new Weld Builder application software, developed to provide intuitive cobot programming. The software, we learned, proves ideal for welding small batch sizes with frequent job changes. And it’s readily learned by employees with little programming experience.

Autonomous Side Loader for Long Loads

Combilift North America debuted its Combi-AGT fully autonomous side loader—reportedly the world’s first—for long loads for use by metal fabricators and steel service centers. It features a lift capacity of 11,000 lb. and various lift heights.

Combilift North America debuted its Combi-AGT fully autonomous side loader—reportedly the world’s first—for long loads for use by metal fabricators and steel service centers. It features a lift capacity of 11,000 lb. and various lift heights.

With this side loader, fabricators reportedly can deliver long loads in narrow aisles around the clock safely and reliably without an operator. The Combi-AGT helps fully automate existing infrastructure, using common features with no extra functions, and can be integrated with a fabricator’s warehouse-management system for full autonomy.

The development of the autonomous side loader was driven in part by safety to eliminate the presence of personnel in potentially hazardous aisles, consistency in handling procedures, and to maximize order fulfilment, the company reports.

Based on the electric manually operated Combi- GTE model, which works efficiently in rail-guided narrow aisles, this new side loader can operate either autonomously in guided aisles or be free-roaming with a manual driving option.

Integrating External Axes Enables More-Sophisticated UR-Cobot Applications

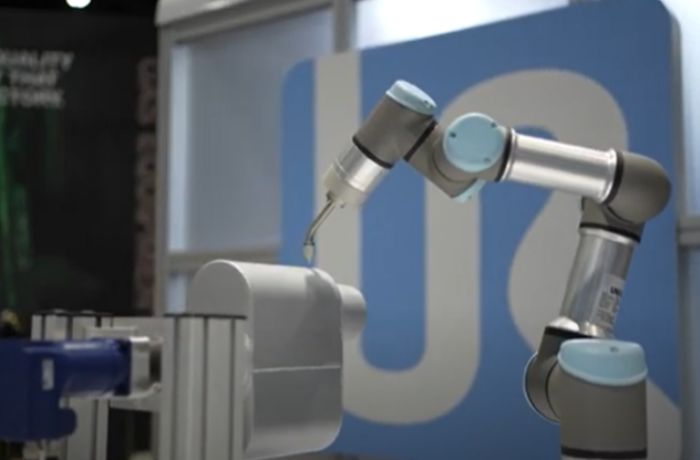

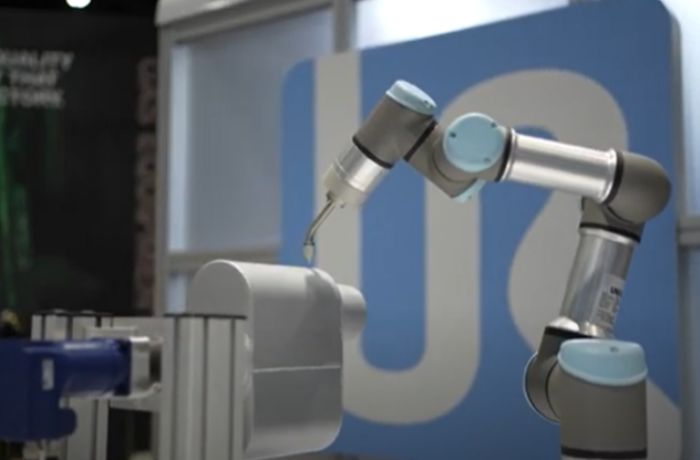

Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s cobots. The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s controller.

Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s cobots. The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s controller.

“Having the cobot sync with a rotary positioner or a linear rail, and timing it within milliseconds, means that users now can weld parts efficiently whereas before they normally couldn’t because they’d either have to stop and manually move the part, or weld it at two different times,” explains Will Healy III, global industry leader of welding at Universal Robots.

MotionPlus enables these capabilities, allowing UR’s welding partners to add dual-axis coordinated motion capabilities to their own solutions. For example:

Vectis Automation leveraged MotionPlus, launching the Revo dual-axis system at FABTECH. The new multi-axis positioning method can tackle more complex multi-faceted parts and excel in situations where the fabricator must orient parts relative to gravity. Vectis also showcased QuickTeach and AI Path Optimization. QuickTeach allows the cobot user to teach points and optimize paths right at the torch. AI Path Optimization applies user-defined work angles, push/pull angles and smoothed corner transitions to the weld path, thus ensuring that the weld always is created according to procedure specifications.

THG Automation demonstrated multi-axis welding through THG Multi-motion, featuring a dual-axis skyhook with a part welded by a UR cobot mounted on a rail. THG also launched THG-Multi-Op: two all-in-one systems, one for gas-metal-arc/tungsten-metal-arc welding, and another for cutting and welding. Each system employs a tool changer that allows the operator to switch easily between applications. Other new THG products at FABTECH included a laser welding system and a new mobile base that provides user flexibility in orienting a cobot system with unusually sized and shaped parts. MF

Industry-Related Terms: Bed,

Bending,

Cam,

Corner,

Die,

Edge,

Form,

Forming,

Hardware,

Laser Welding,

LASER,

Model,

Pallet,

Penetration,

Piercing,

Ram,

Spatter,

Stainless Steel,

Stroke,

Thickness,

Torque,

FormingView Glossary of Metalforming Terms

See also: TRUMPF Inc., Yaskawa America, Inc., Mid Atlantic Machinery Inc., Gudel, Inc., Macrodyne Technologies, Inc.

Technologies: Management

Zani SpA announced the launch of a new line of presses, the Servo Smart series, due out by year’s end. Designed to provide flexibility, increased productivity, lower energy consumption, and reduced maintenance and die wear, Servo Smart presses are available in 200-, 300- and 400-ton models.

Zani SpA announced the launch of a new line of presses, the Servo Smart series, due out by year’s end. Designed to provide flexibility, increased productivity, lower energy consumption, and reduced maintenance and die wear, Servo Smart presses are available in 200-, 300- and 400-ton models. Among Amada’s technology innovations debuting for North American audiences at FABTECH, the Regius 3015 AJe 26-kW fiber laser cutting machine. The high-wattage model features a high-speed, three-axis linear drive that softens ramp-up and ramp-down traverse speeds to achieve high-speed, high-precision cutting. The linear drive achieves 5-g acceleration and reaches traverse speeds of 13,300 in./min., reducing nest times by 15% as compared to Amada’s previous linear-driven machine.

Among Amada’s technology innovations debuting for North American audiences at FABTECH, the Regius 3015 AJe 26-kW fiber laser cutting machine. The high-wattage model features a high-speed, three-axis linear drive that softens ramp-up and ramp-down traverse speeds to achieve high-speed, high-precision cutting. The linear drive achieves 5-g acceleration and reaches traverse speeds of 13,300 in./min., reducing nest times by 15% as compared to Amada’s previous linear-driven machine.

Integrator Mid Atlantic Machinery Inc. showcased its AutoTend robotic machine-tending setup, which employs a Universal Robots UR10e cobot to tend a press brake. At FABTECH, the cobot was teamed with a Trumpf TruBend 7036 press brake to form, via complex bends, type 304 stainless steel into a candy dish.

Integrator Mid Atlantic Machinery Inc. showcased its AutoTend robotic machine-tending setup, which employs a Universal Robots UR10e cobot to tend a press brake. At FABTECH, the cobot was teamed with a Trumpf TruBend 7036 press brake to form, via complex bends, type 304 stainless steel into a candy dish.  Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.

Güdel highlighted its cam-follower advantage: Güdel’s cylindrical roller bearing mounted on a stud that rides on the guide rail, reportedly providing significantly increased resilience to harsh industrial environments as compared to traditional profile guides commonly used in seventh-axis tracks.  Trumpf unveiled its flat-sheet laser cutting machine, the TruLaser Series 3000 Bevel Cut Edition, which automatically prepares part edges for welding. It can produce beveled cutting edges, or chamfers, on the top and bottom of components while cutting, ensuring optimum preparation of welding edges and reducing downstream processes. Particularly suited for mild and stainless steel, the machine applies chamfers to sheets in thicknesses to

Trumpf unveiled its flat-sheet laser cutting machine, the TruLaser Series 3000 Bevel Cut Edition, which automatically prepares part edges for welding. It can produce beveled cutting edges, or chamfers, on the top and bottom of components while cutting, ensuring optimum preparation of welding edges and reducing downstream processes. Particularly suited for mild and stainless steel, the machine applies chamfers to sheets in thicknesses to  Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press brake cell (pictured), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser cutting machines.

Highlighting the dizzying array of equipment displayed at the Bystronic FABTECH exhibit were two new products targeting the ever-growing need for fab shops to automate their operations: the ByCell Bend Star M compact automated press brake cell (pictured), designed to fill the gap between the firm’s smaller mobile bending robot and its larger bending cell; and the ByLoader Flex 3015 sheet-handling system for laser cutting machines.  Spartan Robotics introduced a smart cobot welder featuring a unique Kassow Robots seven-axis arm. The seventh axis facilitates better welding because it provides enhanced flexibility and precision, according to Spartan Robotics officials. The extra axis allows welders to navigate around challenging weld locations and tight spaces and to perform complex weld patterns. The setup also features an integrated free-drive button that enables programming of all cobot positions at one time. Users can choose pre-engineered or custom machine designs.

Spartan Robotics introduced a smart cobot welder featuring a unique Kassow Robots seven-axis arm. The seventh axis facilitates better welding because it provides enhanced flexibility and precision, according to Spartan Robotics officials. The extra axis allows welders to navigate around challenging weld locations and tight spaces and to perform complex weld patterns. The setup also features an integrated free-drive button that enables programming of all cobot positions at one time. Users can choose pre-engineered or custom machine designs. Opening the door for the next stage of robotic automation and leveraging machine learning and artificial intelligence (AI) for more intelligent robotic systems, Yaskawa Motoman launched the Motoman Next platform. Company officials report that the platform is the first in the industrial-robot sector to have autonomous adaptivity and an open development environment that facilitates increased communication and expandable functionality, equipping robots with the ability to execute challenging tasks autonomously in unstructured environments.

Opening the door for the next stage of robotic automation and leveraging machine learning and artificial intelligence (AI) for more intelligent robotic systems, Yaskawa Motoman launched the Motoman Next platform. Company officials report that the platform is the first in the industrial-robot sector to have autonomous adaptivity and an open development environment that facilitates increased communication and expandable functionality, equipping robots with the ability to execute challenging tasks autonomously in unstructured environments. Combilift North America debuted its Combi-AGT fully autonomous side loader—reportedly the world’s first—for long loads for use by metal fabricators and steel service centers. It features a lift capacity of 11,000 lb. and various lift heights.

Combilift North America debuted its Combi-AGT fully autonomous side loader—reportedly the world’s first—for long loads for use by metal fabricators and steel service centers. It features a lift capacity of 11,000 lb. and various lift heights. Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s cobots. The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s controller.

Universal Robots (UR) highlighted its new MotionPlus package that promises a simple and accurate way to integrate external axes—axes that maneuver parts undergoing operations with UR’s cobots. The package helps the cobots “go beyond the cart,” a UR show theme that refers to expanding the work envelope in cobot applications. FABTECH served as a launch pad for several related partner applications, such as dual-axis cobot welding with coordinated motion managed through a UR cobot’s controller.